Our Gutter Roll Forming Machine is a fully automated production line designed for the high-volume, precision manufacturing of continuous-length gutter systems from metal coils. It seamlessly transforms raw materials—such as pre-painted aluminum, galvanized steel, or copper coils—into finished gutters with consistent profiles, superior strength, and impeccable aesthetics. This system is the cornerstone of efficiency for building material suppliers, metal roofing factories, and construction companies looking to scale their production and dominate the market.

Gutter Roll Forming Machine

- High Efficiency & Automation: Features an automatic uncoiler and cutting system for continuous operation with minimal manual intervention, dramatically increasing output.

- Precision Engineering: Utilises a robust roll forming system to ensure consistent profile shape, tight lock seams, and superior dimensional accuracy.

- PLC Control System: An intuitive touch-screen PLC (Programmable Logic Controller) allows for precise adjustment of production parameters, including pipe length, quantity, etc. Fault diagnostics ensure easy operation and maintenance.

- Customizable Length: Integrated precision flying cut-off unit cuts the formed downpipe to pre-set lengths without stopping the line, ensuring clean, burr-free ends.

- Durability & Reliability: Built with heavy-duty steel frames and high-quality components to ensure stable performance, low maintenance, and a long service life in demanding industrial environments.

| Material | Type | GI, PPGI, Aluminum coils |

| Thickness(mm) | 0.3-0.8(Customizable) | |

| Yield Strength(Mpa) | 230-350 | |

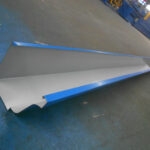

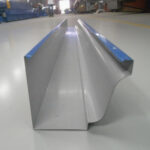

| Gutter Profile | K-Style, Ogee, Half-Round, Gutter,etc | |

| Forming Speed(m/min) | 15-25 | |

| Roller Station | Depends | |

| Roller Material | 45# steel with hard chrome treatment | |

| Roller Driven Type | Chain transmission/Gearbox | |

| Shaft Material | 45# steel with heat treatment | |

| Shaft Diameter | Depends | |

| Control System | PLC+Touch screen and button | |

| Main Machine Power(KW) | 7.5 | |

| Hydraulic station Power(KW) | 4 | |

| Machine Weight(Kg) | 6000 | |

| Machine size(m) | 8.5×1.8×1.7 Depend on final design | |

- Decoiler – Holds and feeds steel coils smoothly into the line.

- Levelling System – Ensures flat, uniform material before forming.

- Pre-Punching(Optional)–Before forming a punching unit can accurately create downpipe outlet holes and other necessary Features.

- Roll Forming Unit – Precision-engineered rollers shape steel into different profiles with accuracy.

- Hydraulic Cutting System – Provides fast, clean, and burr-free cuts to required lengths.

- Control System (PLC + Touch Screen) – User-friendly interface for automatic operation and easy adjustments.

- Output Table – Collects finished products for efficient handling and packaging.

The gutter roll forming machine is the application of modern industrial automation to a fundamental building component. It is the enabling technology for efficient, high-quality, and cost-effective production of rainwater management systems, making it a critical asset for any serious player in the metal building products industry.

Contact Form

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.

Scan the code

Welcome to Metoform Tech

Can we help you?

Open Chat