What is the Difference Between Hot Rolled and Cold Rolled Steel?

Steel is one of the most widely used materials in construction, manufacturing, and processing. Among the many forms of steel, hot rolled steel and cold rolled steel are the two most common.

Although they originate from similar raw materials, their production processes, surface properties, mechanical properties, and applications differ significantly. In this article, we will analyze the differences between these two materials.

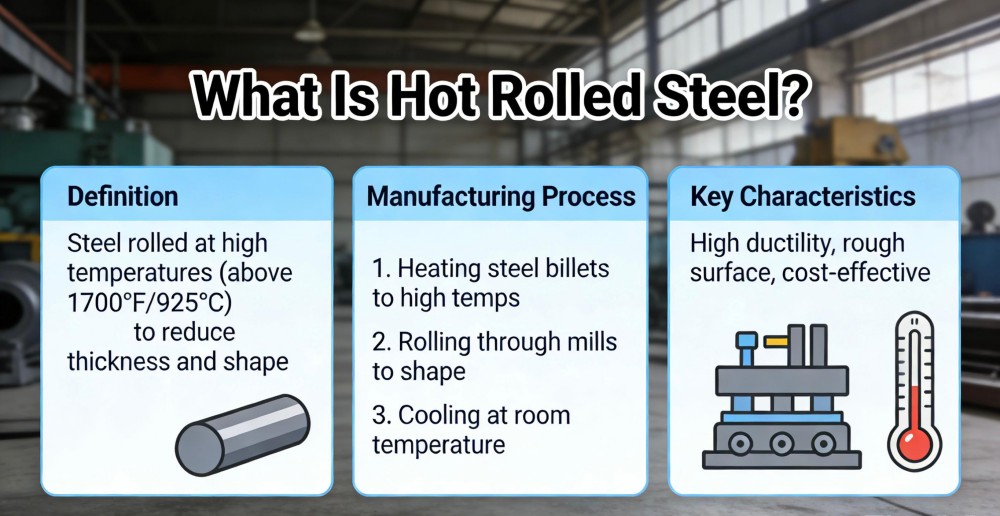

What Is Hot Rolled Steel?

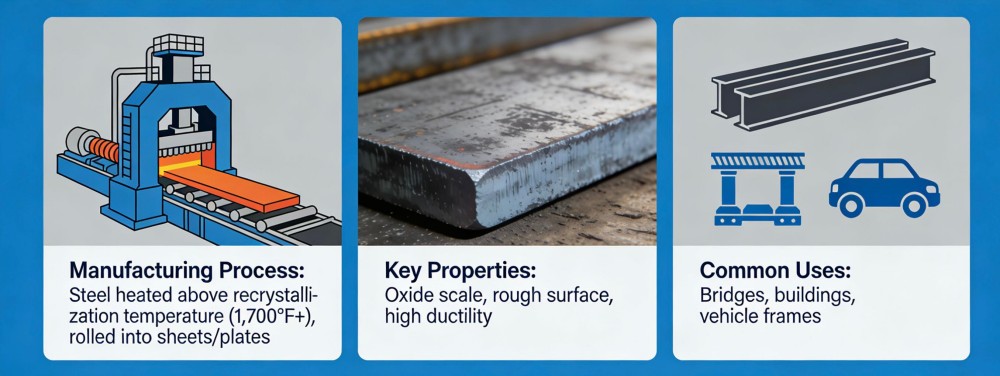

Hot rolled steel is made by rolling steel at extremely high temperatures, typically above 1700°F, which is higher than the recrystallization temperature of the steel. At this temperature, the steel is easily shaped. Once the desired shape is achieved, the steel cools naturally.

Because the rolling process takes place at high temperatures, precise dimensional control is more difficult. The material may shrink slightly as it cools, leading to increased tolerances.

Characteristics of Hot Rolled Steel

Hot rolled steel, due to its high-temperature heating and air cooling, has a rougher, scaly surface. Its edges and corners are typically rounded rather than sharp. Dimensional deviations are more common in hot rolled steel compared to cold rolled products.

From a mechanical property perspective, the yield strength of hot rolled steel is generally lower than that of cold rolled steel, but it is still suitable for applications where tolerances and surface appearance requirements are not stringent.

Advantages of Hot Rolled Steel

Hot rolled steel is generally cheaper than cold rolled steel because its production process requires no delays and no secondary heating like cold-rolled steel. Furthermore, since hot rolled steel cools at room temperature, it is essentially normalized. This means it does not generate internal stresses like quenching or work hardening processes.

Applications of Hot Rolled Steel

One of the many differences between hot rolled and cold rolled steel is price. Hot rolled steel is generally cheaper than cold rolled steel because its production process requires no delays and no secondary heating like cold rolled steel. Hot rolled steel can be used in applications where shape and tolerance requirements are not stringent, such as:

- Structural components (rails, I-beams, sheet metal)

- Agricultural equipment

- Metal construction

- Stamping

- Automotive frames

What Is Cold Rolled Steel?

Cold rolled steel is made by cooling hot-rolled steel. It is then further processed through an additional rolling process at or near room temperature. This cold-working process increases the material’s strength and improves dimensional accuracy.

Because the steel is formed after cooling, cold rolling allows for smaller tolerances and a smoother, more uniform surface finish.

Advantages of Cold Rolled Steel

Cold rolled steel typically results in smoother product surfaces, tighter tolerances, and a finer finish. Furthermore, cold rolled steel has a smooth surface with a slightly oily feel. Other advantages include:

- Suitable for precision applications

- Harder and stronger than hot-rolled steel

- Increased hardness, enhanced tensile strength, and improved resistance to deformation (due to work hardening)

- Aesthetically pleasing surface finishes and a wider range of surface treatment options

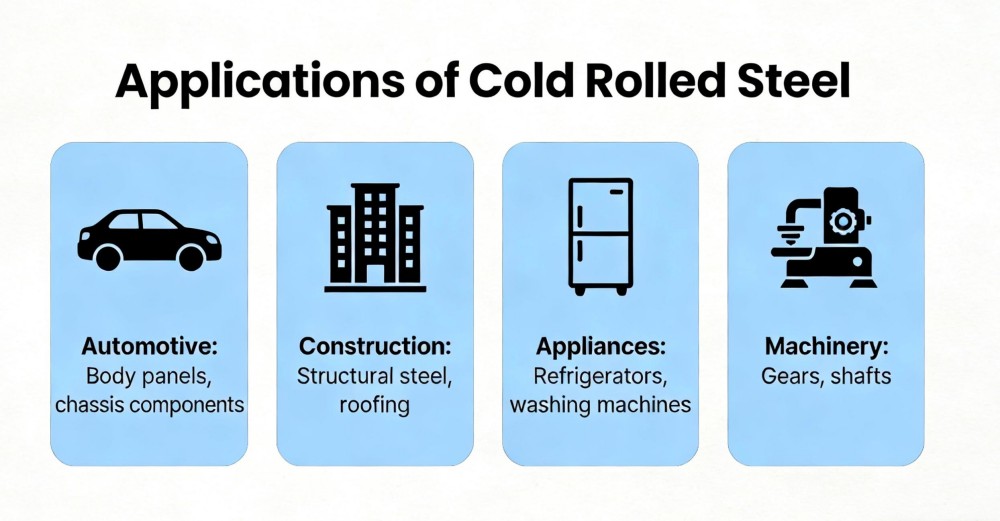

Applications of Cold Rolled Steel

Cold rolled steel is suitable for applications requiring high tolerances, surface finish, concentricity, and straightness. It also provides a more aesthetically pleasing and visually appealing surface.

Other applications include:

- Home appliances

- Metal furniture

- Aerospace structural components

- Automotive parts

Key Differences Between Hot Rolled and Cold Rolled Steel

| Aspect | Hot Rolled Steel | Cold Rolled Steel |

| Processing temperature | High | Room temperature |

| Surface finish | Rough, scaled | Smooth, uniform |

| Dimensional tolerance | Looser | Tighter |

| Strength | Lower yield strength | Higher yield strength |

| Cost | Lower | Higher |

| Typical uses | Structural and industrial | Precision and appearance-focused |

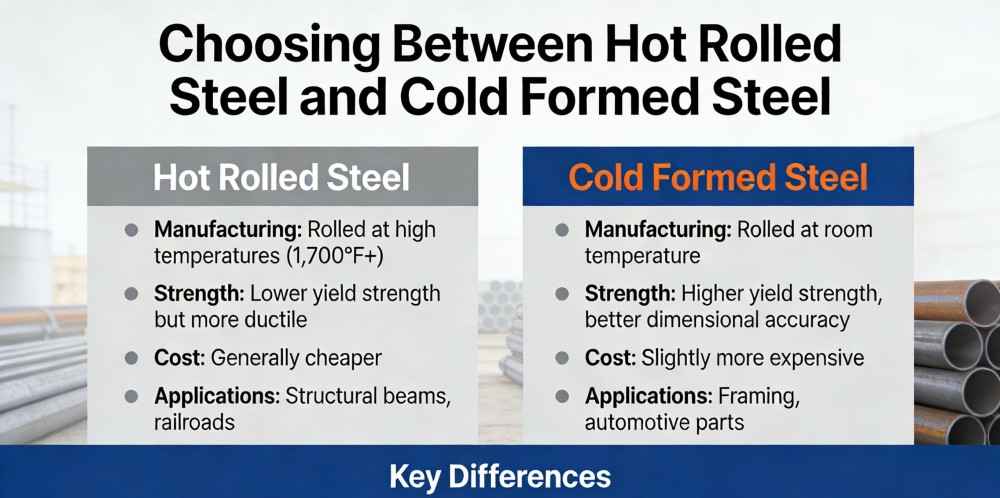

Choosing Between Hot Rolled Steel and Cold Formed Steel

Cold formed steel refers to steel that is shaped at room temperature into profiles such as channels, studs, or tubes. It is often made from cold rolled or galvanized steel.

When deciding between hot rolled steel and cold formed steel, consider the following factors:

Load requirements: Hot rolled steel is commonly used for heavy structural loads.

Dimensional accuracy: Cold formed steel provides consistency for framing systems.

Fabrication method: Cold formed steel is easier to assemble with screws and fasteners, while hot rolled steel is often welded.

Project scale: Large infrastructure projects often rely on hot rolled steel, while modular and light construction favors cold formed steel.

Matching the steel type to structural needs, fabrication methods, and budget helps ensure efficient material selection.

Conclusion

Hot-rolled steel and cold-rolled steel have different applications in the steel industry. Hot-rolled steel is produced at high temperatures and is suitable for structural and industrial applications where surface finish and tolerance requirements are not high.

Cold rolled steel, on the other hand, undergoes further processing at lower temperatures to improve strength, surface quality, and dimensional accuracy. Neither is inherently superior or inferior; each has its own suitable applications.

FAQs

1、Is hot rolled steel weaker than cold rolled steel?

Hot rolled steel generally has lower yield strength than cold rolled steel due to the absence of strain hardening during cold processing.

2、Why does cold rolled steel cost more?

Cold rolled steel requires additional processing steps, which increases production time and cost.

3、Can hot rolled steel be used for precision parts?

It can be used, but additional machining is often needed to meet tight tolerances.

4、Is cold rolled steel suitable for welding?

Yes, though higher strength may require adjustments in welding techniques.

5、Which steel type is better for outdoor use?

Both can be used outdoors, but corrosion resistance depends more on coatings and treatments than on rolling method.

Product Recommendation

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.