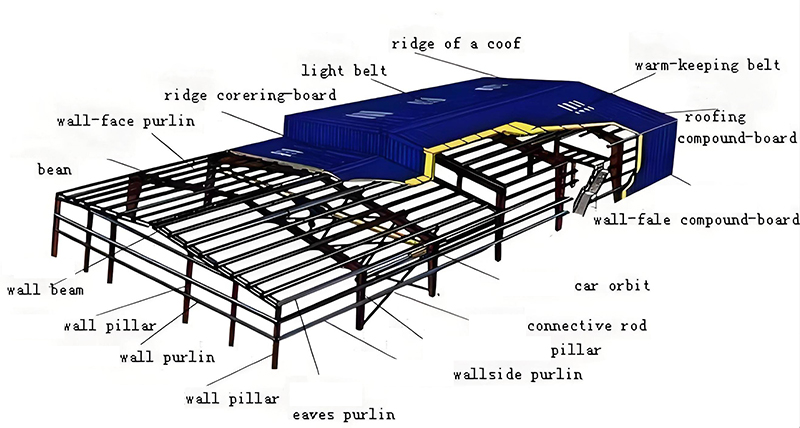

Roof purlins are horizontal structural members in a roofing system, spanning between rafters or trusses to provide direct support for the roof panels or roof covering material. They are typically made of cold-formed steel, such as C- or Z-shaped profiles. Purlins play a crucial role in distributing roof loads (including wind pressure, snow accumulation, and the self-weight of the roofing material) across the main structural frame. In this way, they help limit roof deflection, reduce the risk of roof sagging, and contribute to improving the overall lateral stability of the roof structure.

Choosing the Correct Purlin for Roof Framing

When designing any new roof or renovating an existing one, it is crucial to check all technical parameters to achieve perfection. A well-designed roof is the ideal solution for protecting us from extreme weather and various natural disasters.

The roof is the most important component of any industrial building and needs to be kept stable and properly maintained. Currently, most metal buildings use gently sloping roof designs for a safe and economical construction solution.

When the roof slope is gentle, a negative pressure is generated on the roof, attempting to lift the roof panels upwards.

The long-term performance of a roof framing system depends not only on rafters and trusses. Purlins are often overlooked but crucial components. Roof stability can be achieved by selecting the appropriate purlin spacing and roof profile.

This article will explain what purlins are, their main functions, common types, and practical considerations for selecting the right purlins for your roof framing.

What Are Purlins?

Purlins are secondary structural members that form the framework of a metal building. They are longitudinal horizontal members that connect the longitudinal rafters of a building.

The structural support of every building consists of purlins. Their primary function is to provide intermediate support for the roof panels or roof slabs and to transfer loads to the main structural frame.

In metal and steel structures, purlins are typically made of cold-formed steel. Purlins are parallel to the ridge line and arranged at regular intervals according to the roof design, material type, and expected loads.

Because purlins directly support the roof material, their selection must take into account environmental conditions, roof geometry, and structural requirements.

What Are The Main Functions of Purlins?

Purlins perform several interconnected functions within a roof framing system.

Load Distribution

One of the primary roles of purlins is to distribute roof loads evenly across the supporting structure. These loads include the weight of roofing materials, insulation, maintenance traffic, wind pressure, and in some regions, snow accumulation. By spreading loads over multiple supports, purlins help reduce stress concentrations on rafters or trusses.

Structural Stability

Purlins contribute to the overall stiffness of the roof structure. They help prevent excessive deflection and reduce the risk of roof deformation under varying load conditions. In steel structures, purlins also assist in controlling lateral movement of the primary frame.

Support for Roofing Materials

Roof sheets, panels, and tiles require consistent support to maintain alignment and prevent sagging. Purlins provide a secure fixing surface for fasteners and ensure proper spacing for different roofing materials.

Ease of Installation

Using purlins allows for standardized spacing and simplifies the installation process for roof coverings. This is particularly valuable in large-span or industrial buildings, where efficiency and repeatability are important.

What are the different types of Purlins?

Purlins are available in several shapes and materials, each suited to specific structural and environmental conditions.

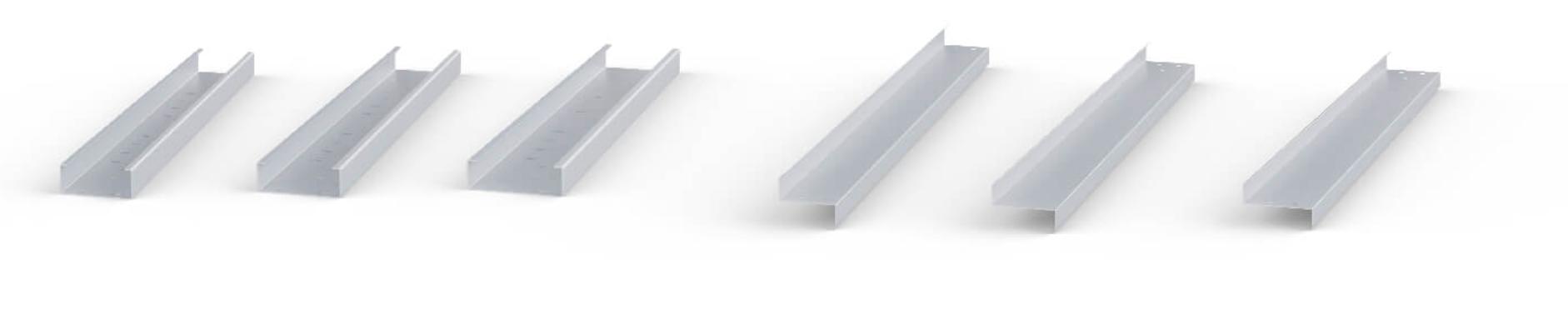

C-Section Purlins

C-section purlins have a profile resembling the letter ”C.”

They are commonly used in roof edges, wall framing, and shorter spans.

These purlins are relatively easy to install and connect, making them suitable for light to medium load applications.

Z-Section Purlins

Z-section purlins are widely used in steel buildings due to their overlapping capability.

This overlap increases structural continuity and improves load transfer across multiple spans.

Z-purlins are often selected for larger buildings where longer spans and higher loads are expected.

Angle Purlins

Angle purlins are traditionally used in timber or steel roof systems with moderate load requirements.

While they are less common in modern large-scale steel construction, they can still be found in smaller structures or retrofitting projects.

Timber Purlins

Timber purlins are typically used in residential or traditional construction. They offer ease of cutting and handling but may require treatment to protect against moisture, insects, and decay. Timber purlins are more sensitive to environmental conditions compared to steel options.

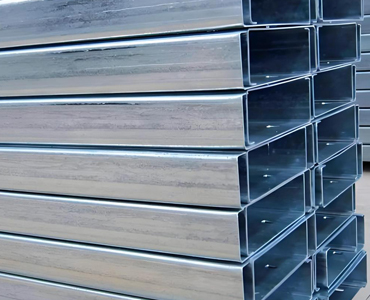

Cold-Formed Steel Purlins

Cold-formed steel purlins are manufactured for consistency and strength. They offer uniform dimensions, corrosion-resistant coatings, and compatibility with modern roofing systems. These purlins are commonly used in commercial and industrial buildings.

Tips For Choosing the Best Purlin For Roof Framing

When designing any structural member, we need to determine the loads acting on it. To determine the loads, the complete parameters of the building should be considered, such as width, length, height, roof slope, and wind speed.

1. Loads on Purlins

The dead load of the roof system includes the self-weight of the roof panels, solar panels, roof terraces, ventilation equipment, walkways, etc.

- Live Loads of the Roof System

- Wind Loads (External Loads)

- Lateral Loads (Suspended Loads on Purlins)

2. Bracing Type

The second important factor is the bracing type, i.e., whether single-span bracing is used or continuous span bracing is achieved through overlapping purlins.

CEE members are typically used as simply supported purlins, while ZEE or ZED purlins are used as continuous span bracing because we can use overlapping purlins.

3. Purlin Span

The third important factor is the purlin span, i.e., the span distance or rafter spacing. The strength and deflection of the purlins will be determined based on the span.

The design of purlins depends on the roofing system. For example, if a screw-fixed system is used at the top of the purlins, the screw profiles form a partition, providing support strength for the purlins.

In the case of a vertical joint roof where the profiles are fixed to the top of the purlins, in addition to moment and deflection checks, lateral torsional buckling of the purlins also needs to be checked.

Cold-formed purlins must be designed according to cold-formed design specifications.

4. Purlin Type Selection and Design Optimisation

Compared to hot-rolled ISMC channel steel and other hot-rolled tube purlins, cold-formed Z-shaped purlins are currently the most economical solution. Hot-rolled purlins are heavier.

Furthermore, because they cannot overlap, they must be designed as simply supported sections, which limits optimization.

Cold-formed Z-shaped steel purlins, on the other hand, are thin, ranging in thickness from 1.2mm to 3.15mm, and can be overlapped to different lengths, allowing for the design of optimal purlin sections. On average, using cold-formed Z-shaped steel purlins can reduce weight by 30% to 50%.

5. Purlin Surface Treatment

Cold-formed purlins are rolled from pre-galvanized steel coils, with a minimum zinc coating thickness of 120 g/m² and a maximum of 275 g/m².

If the environment is controlled and far from coastal and chemical industries, such as warehouses, small manufacturing plants, or factories that do not generate chemicals, a 120 g/m² coating is sufficient.

For other chemical and coastal environments, at least 275 g/m² of coating is required. For highly corrosive environments, the zinc coating thickness can be further increased, or an anti-corrosion coating can be applied to the purlins. Additionally, ceiling materials can be used to seal the purlins.

Conclusion

Purlins are a fundamental component of roof framing systems, providing support, stability, and load distribution for various building types.

By considering factors such as load requirements, span, environmental exposure, roofing materials, and installation methods, purlins can be selected to ensure long-term structural performance and construction efficiency.

A carefully chosen purlin system helps create a roof structure that remains reliable in daily use and under constantly changing environmental conditions.

Product Recommendation

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.