Purlins are essentially horizontal beams used for structural support in buildings, typically roofs. They are supported by rafters or walls and, in turn, support the roof slabs above them. Purlins must be strong and durable because they must bear enormous weight and are an essential component of the roof structure. They have a wide range of uses, including flooring, wall support, and the decoration of window and door frames.

Facts About Roof Purlins and Their Role in Building Structures

Purlins come in a variety of shapes, sizes, and materials to meet diverse building needs. Whether the project involves a detached house, warehouse, commercial building, or agricultural building, understanding roof purlins is crucial for anyone involved in the design, construction, or renovation.

Below is a comprehensive purlin guide that explains in detail the necessity and importance of purlins in structural engineering or construction.

The Importance of Purlins in Building Construction

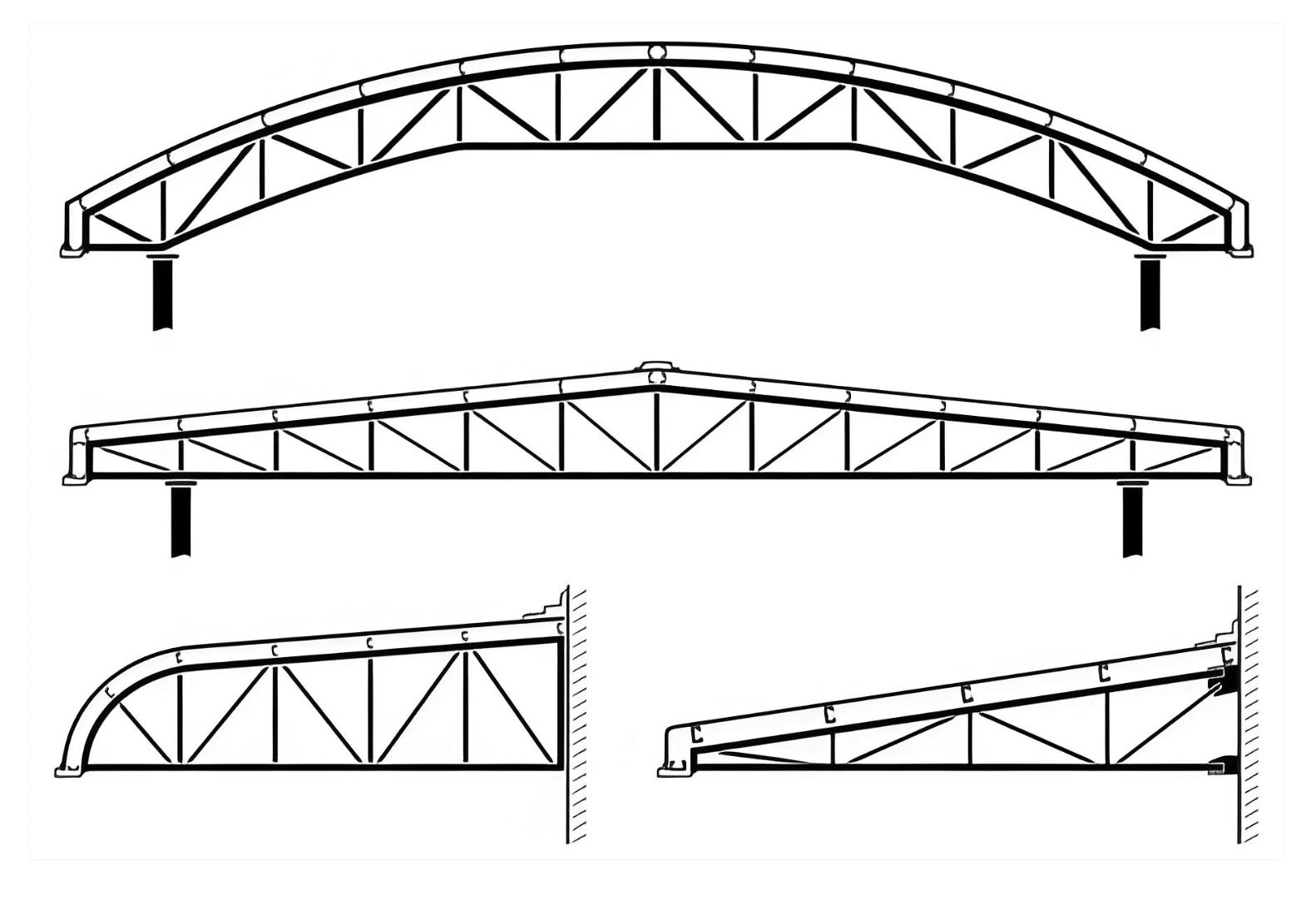

Purlins play a significant role in architectural and structural construction by providing intermediate support for roof systems and helping distribute loads evenly across the building frame.

Installed between rafters or trusses, purlins serve as a base for roof decking and roof coverings, including metal sheets, cladding panels, and insulation systems.

By transferring loads from the roof surface to the primary structural members, purlins help reduce the effective span of rafters or trusses.

This allows for longer roof spans and more open interior spaces without compromising structural performance. For these reasons, purlins contribute directly to roof stability and the overall integrity of the building structure.

Different Shapes of Purlins

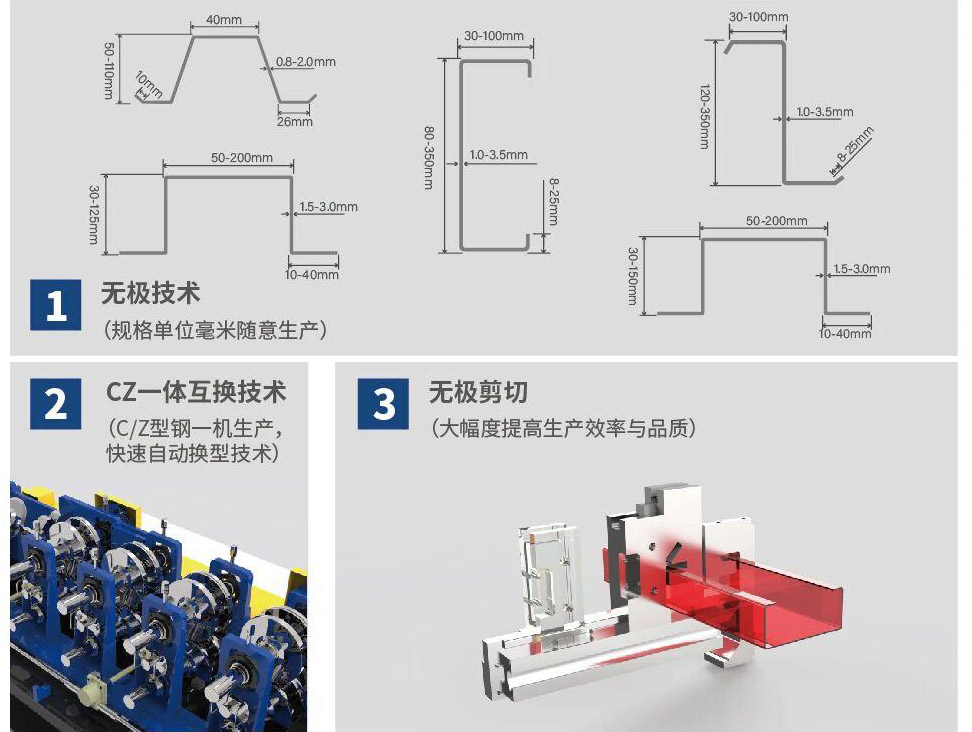

Steel purlins are commonly manufactured in two primary profiles: C-shaped and Z-shaped sections.

C-shaped purlins have a profile similar to the letter “C” and are widely used in wall framing, floor systems, and roof applications where spans are relatively moderate. Their simple geometry allows for straightforward installation and connection to supporting members.

shaped purlins feature a profile resembling the letter “Z”and are frequently used in roofing systems that require overlapping at supports. This overlapping capability improves load transfer and structural continuity across longer spans.

Z purlins are often selected for applications where higher strength and efficient load distribution are required, particularly in metal building shells and large-span structures.

Components of Secondary Framing: Girts and Purlins

In many pre-engineered metal buildings, purlins and girts form the secondary framing system. Purlins support the roof, while girts provide horizontal support for wall cladding. Together, they transfer loads from the roof and wall surfaces to the primary framing and ultimately to the foundation.

In addition to carrying surface loads, purlins and girts act as lateral restraints for the compression flanges of primary structural members. This restraint improves the performance of the main frame by limiting lateral movement and increasing overall structural stability.

Purlin Span

Purlin span refers to the distance between the centers of the supporting cleat bolts at each end of the purlin. Span configuration affects how loads are distributed and how the purlin performs under service conditions.

- Single-span purlins are supported only at their ends, with the web bolted directly to cleats or other rigid supports.

- Double-span purlins are supported at both ends and at a central intermediate support.

- Continuous-span purlins extend over multiple supports, being supported at each end and at regularly spaced intermediate points.

- Each span configuration is selected based on roof geometry, load requirements, and structural design considerations.

Purlin Accessories

Various accessories are used in conjunction with purlins to improve roof performance and simplify installation. Common accessories include purlin laps, cleats, and connection hardware.

Purlin laps provide continuity between adjacent purlins and add strength at overlapping points. These laps are typically bolted through pre-punched holes in the web and flange sections.

Cleats are used to create rigid connections between purlins and primary members such as rafters, trusses, beams, wall plates, or studs. Depending on structural requirements, both single and double cleat configurations may be used.

Purlin Design Considerations

Purlins are designed to resist several types of loads, including dead loads from roofing materials, live loads such as maintenance activity, and environmental loads such as wind and snow.

A properly designed purlin must have sufficient strength and stiffness to support these loads throughout its service life.

Deflection control is also an important consideration. Excessive deflection can affect roof appearance and performance, making the roof sheeting appear uneven or misaligned.

Structural design standards and span tables are typically used to ensure that purlins meet these requirements.

Purlin Installation Practices

Installing purlins requires careful attention to safety and proper sequencing. When working at height, appropriate personal protective equipment should always be used.

Purlins, girts, and bridging elements should not be loaded or walked on until they are fully bolted and braced according to the design specifications.

All bolts used during installation must be of the correct grade and size, and they should be tightened to the specified torque to ensure reliable connections. Proper alignment during installation helps maintain roof geometry and simplifies the installation of roofing materials.

Handling and Storage of Purlins

Proper handling and storage are essential to maintain the condition of roof purlins before installation. Purlins should be stored in dry conditions to prevent moisture from becoming trapped between stacked sections, which can lead to early corrosion.

If purlins are exposed to water, they should be separated and restacked in a way that allows airflow to dry the surfaces. Oils or grease left on purlins during manufacturing or transport should also be managed carefully, as they can increase the risk of surface deterioration if not addressed.

Where Roof Purlins Are Used?

The application of roof purlins spans a variety of building types:

Conclusion

As horizontal support components in a roofing system, roof purlins help distribute structural loads, improve overall roof stability, and provide a reliable anchoring surface for metal panels and other roofing materials.

They play a central role in efficient and coordinated structural design. From small residential metal roofs to large commercial and industrial buildings, a thorough understanding of purlin functions and how to select appropriate purlin profiles and configurations is crucial for ensuring the long-term performance and structural reliability of the roof.

Product Recommendation

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.