A Comprehensive Guide to Purlin Roll Forming Machines

In modern construction, the need for precision, efficiency, and durability is more crucial than ever. Purlin roll forming machines are crucial for shaping and forming steel into structural components. These machines have become indispensable in industries such as construction, manufacturing, and infrastructure.

In this guide, we’ll explore the functions, types, and applications of purlin forming machines, as well as their importance in steel structure projects.

What is a Purlin Roll Forming Machine?

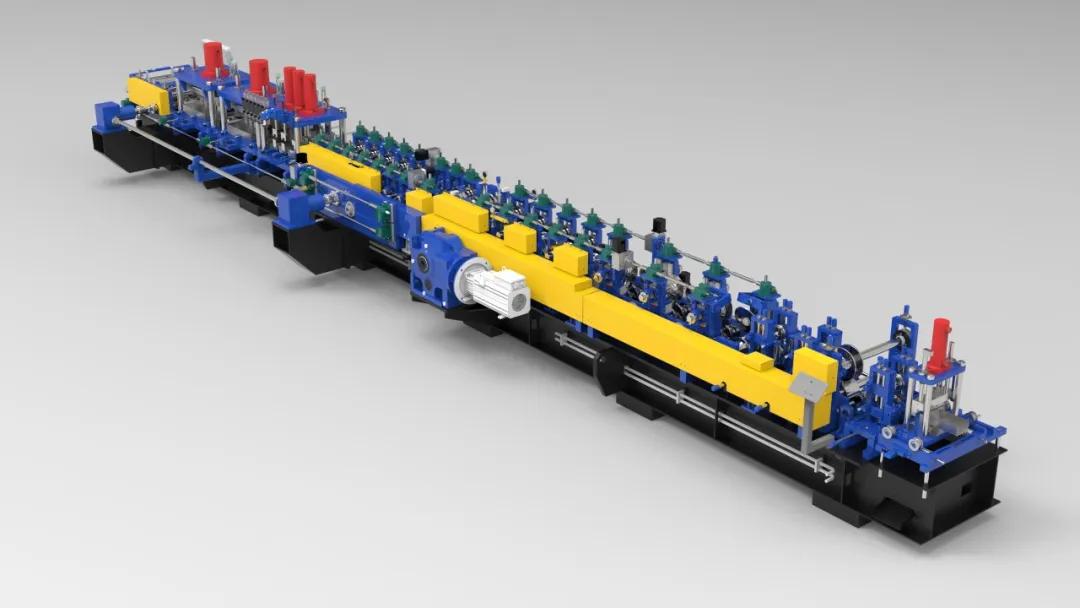

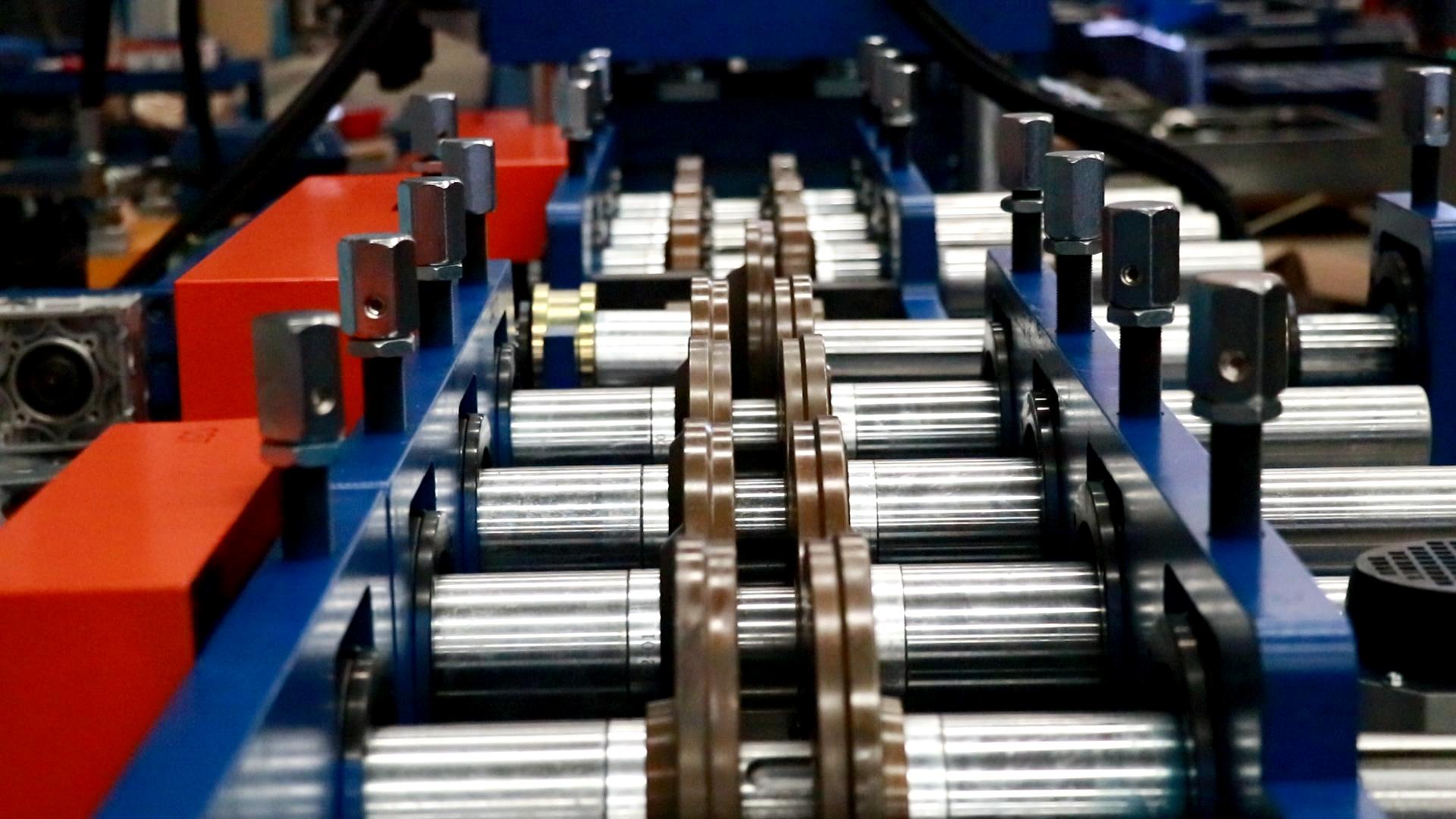

A purlin roll forming machine is designed to manufacture steel purlins—horizontal beams used to support roof structures in buildings. These purlins are typically made from steel, offering strength and durability, essential characteristics for any building project. The roll forming machine feeds a coil of steel through a series of rollers, which gradually shape it into the desired profile. The result is a precisely formed purlin that can be used in construction.

The main benefit of using a steel framing machine, like the purlin roll forming machine, is that it automates the production process, allowing manufacturers to achieve consistency, higher production rates, and reduced material waste. This high level of automation makes it an indispensable tool for creating steel components at scale, providing a significant advantage in both speed and quality.

The Role of Purlins in Construction

Purlins serve a critical function in the structural integrity of a building. They act as horizontal supports for the roof, transferring the load to the main building framework. Purlins not only provide stability to the structure but also play a role in ensuring the roof can bear external forces such as wind, rain, and snow.

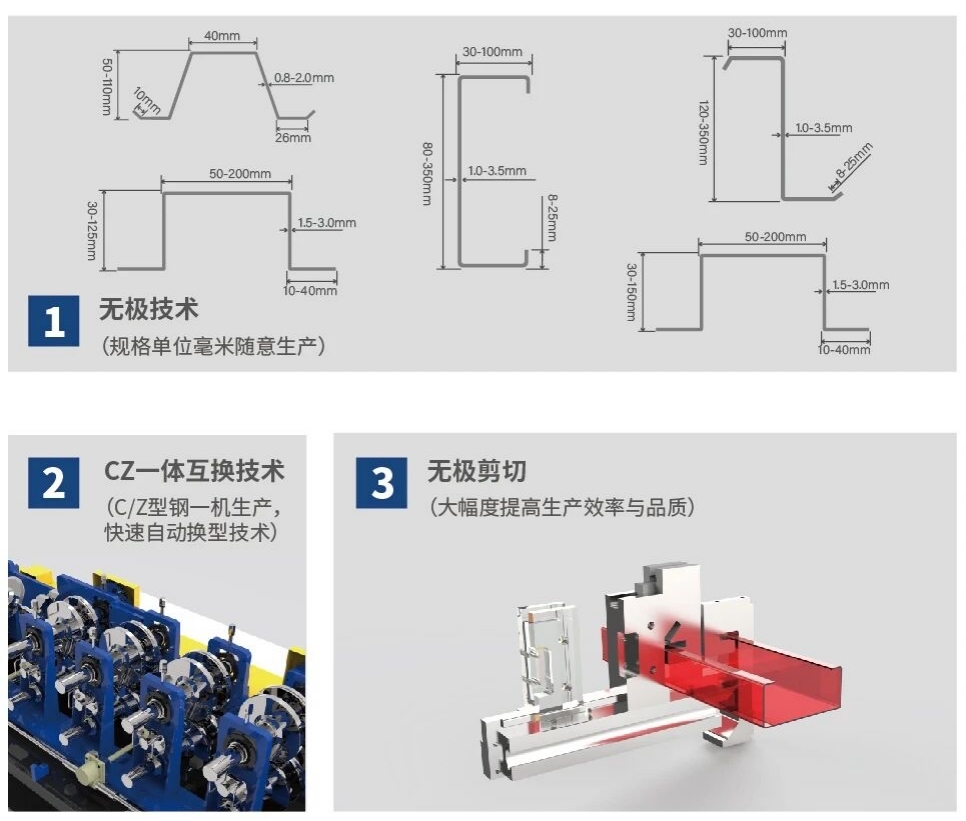

The ability to customise the profiles of CZ purlin machines allows manufacturers to create purlins of various shapes and sizes, making them adaptable to different construction needs. C purlins are often used in lighter, smaller projects, while Z purlins are chosen for larger structures requiring greater strength and load-bearing capacity.

Types of Purlin Roll Forming Machines

Purlin roll forming machines come in different varieties, designed to create specific purlin profiles. The most common types of these machines include the C purlin roll forming machine, the Z purlin roll forming machine, and the more versatile CZ purlin roll forming machine.

The C purlin roll forming machine creates purlins with a C-shaped cross-section, ideal for lighter construction projects where strength is still essential but the load-bearing needs aren’t as heavy. These C-shaped purlins are commonly used for roofs, walls, and other supporting structures.

On the other hand, Z purlins are created by the Z purlin roll forming machine, which produces a Z-shaped profile. These purlins are typically used for larger buildings where stronger support is needed. Z purlins are often used in industrial buildings and warehouses, where long spans and heavy loads are common.

The CZ purlin roll forming machine is versatile, capable of producing both C and Z purlins. This flexibility makes it especially useful for large-scale construction projects where different types of purlins are required. The ability to switch between C and Z profiles ensures manufacturers can meet the specific needs of diverse construction applications.

Key Advantages of Purlin Roll Forming Machines

The purlin machine offers several advantages that make it a preferred choice in the steel framing industry. First and foremost, these machines provide high efficiency. Their automated nature means that purlins can be produced quickly, reducing production time and costs. Manufacturers can produce large quantities of purlins with minimal manual labor, significantly lowering the cost per unit.

In addition, the precision of the roll forming machine ensures that the purlins are uniform in size and shape, meeting the strict specifications required for construction. The consistency offered by these machines also helps reduce material waste, making the entire process more cost-effective.

The durability and strength of steel purlins produced by these machines are another significant advantage. Purlins need to withstand various forces—wind, rain, snow, and even the weight of roofing materials themselves. Steel is one of the strongest materials available, and using a steel framing machine ensures the purlins are robust and capable of supporting the structure for years to come.

Maintenance of purlin roll forming machines is relatively easy, provided they are properly cared for. Well-maintained machines have a long operational life, which helps avoid costly repairs and downtime.

Applications of Purlin Roll Forming Machines

The applications of purlin roll forming machines are vast. They play an integral role in construction projects that require strong and reliable steel framing components. C purlin machines are often used for smaller-scale applications like residential homes or light commercial buildings. These purlins are perfect for roof supports, wall framing, and other structural elements that don’t bear a heavy load.

For more substantial buildings like industrial warehouses or large commercial structures, Z purlin machines are the go-to solution. These machines create purlins that can support heavy roofing materials, large spans, and extreme weather conditions. The interlocking feature of Z purlins also ensures that the structure remains stable and durable over time.

In many large-scale construction projects, a CZ purlin roll forming machine is often the best choice. Its ability to produce both C and Z purlins means that manufacturers can create the exact profiles needed for various parts of a building. This versatility allows for efficient and cost-effective production, catering to the ever-changing needs of construction projects.

Agricultural buildings, too, benefit from purlin machines. These buildings, such as barns and storage facilities, require strong purlins to support the roofing material and resist weather-related stresses. Steel purlins produced by roll forming machines provide the necessary durability to handle these demanding conditions.

Choosing the Right Purlin Roll Forming Machine

When selecting the right purlin roll forming machine, several factors come into play. The first consideration is the type of purlin needed. If your project requires both C and Z purlins, a CZ purlin roll forming machine is the most practical choice. This machine offers the flexibility to adapt to different construction requirements.

Another key factor is the production capacity. If you need to produce large volumes of purlins quickly, investing in a more advanced machine with higher output capabilities would be beneficial. Additionally, it’s important to consider the type of material you plan to use. Ensure that the machine is compatible with the steel grades and thicknesses required for your project.

Customisation is also an important consideration. Some purlin roll forming machines offer adjustable settings, allowing manufacturers to produce different sizes and profiles as needed. This flexibility ensures the machine can meet the specific demands of any construction project, whether small-scale or large.

Conclusion

Purlin forming machines have become a game-changing technology in the construction industry, thanks to their high efficiency, precision, and versatility. These machines enable manufacturers to produce strong, durable steel purlins suitable for a wide range of applications.

Purlin forming machines produce high-quality purlins with minimal waste and lower labor costs, ensuring your construction projects are completed efficiently and cost-effectively. Whether you require C-shaped, Z-shaped, or CZ-shaped purlins, these machines provide the flexibility and precision needed to meet the diverse demands of modern construction.

Product Recommendation

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.