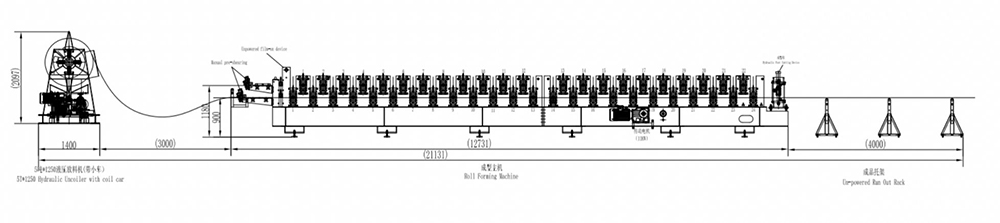

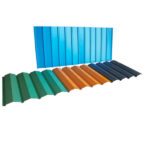

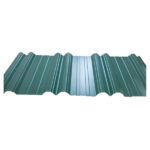

Three layer roll forming machine is a specialized piece of industrial equipment used to continuously produce building panels that consist of three metal layers.

These panels are widely used in the construction industry for roofs and walls due to their excellent efficiency, structural strength, and fast installation.