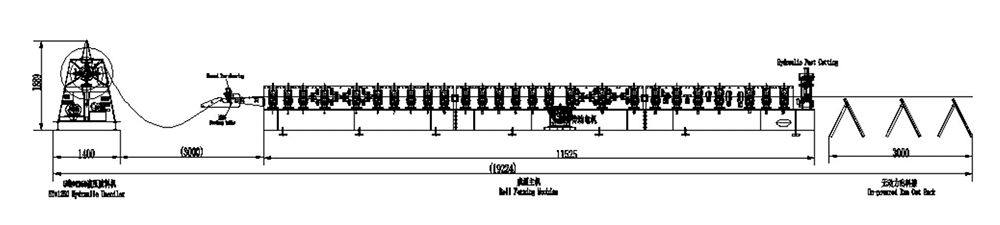

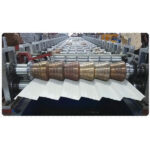

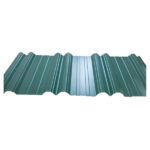

Trapezoid roof sheet making machine is a highly automated production line that transforms a continuous coil of flat metal (typically GI, PPGI, or aluminum) into trapezoidal roof and wall panels.

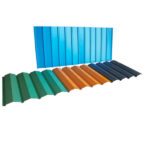

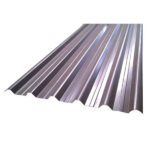

Trapezoidal panels have a distinct angular, trapezoid-like profile, known for its high load-bearing capacity and modern appearance. The machine uses a cold-forming process called roll forming to achieve this shape.