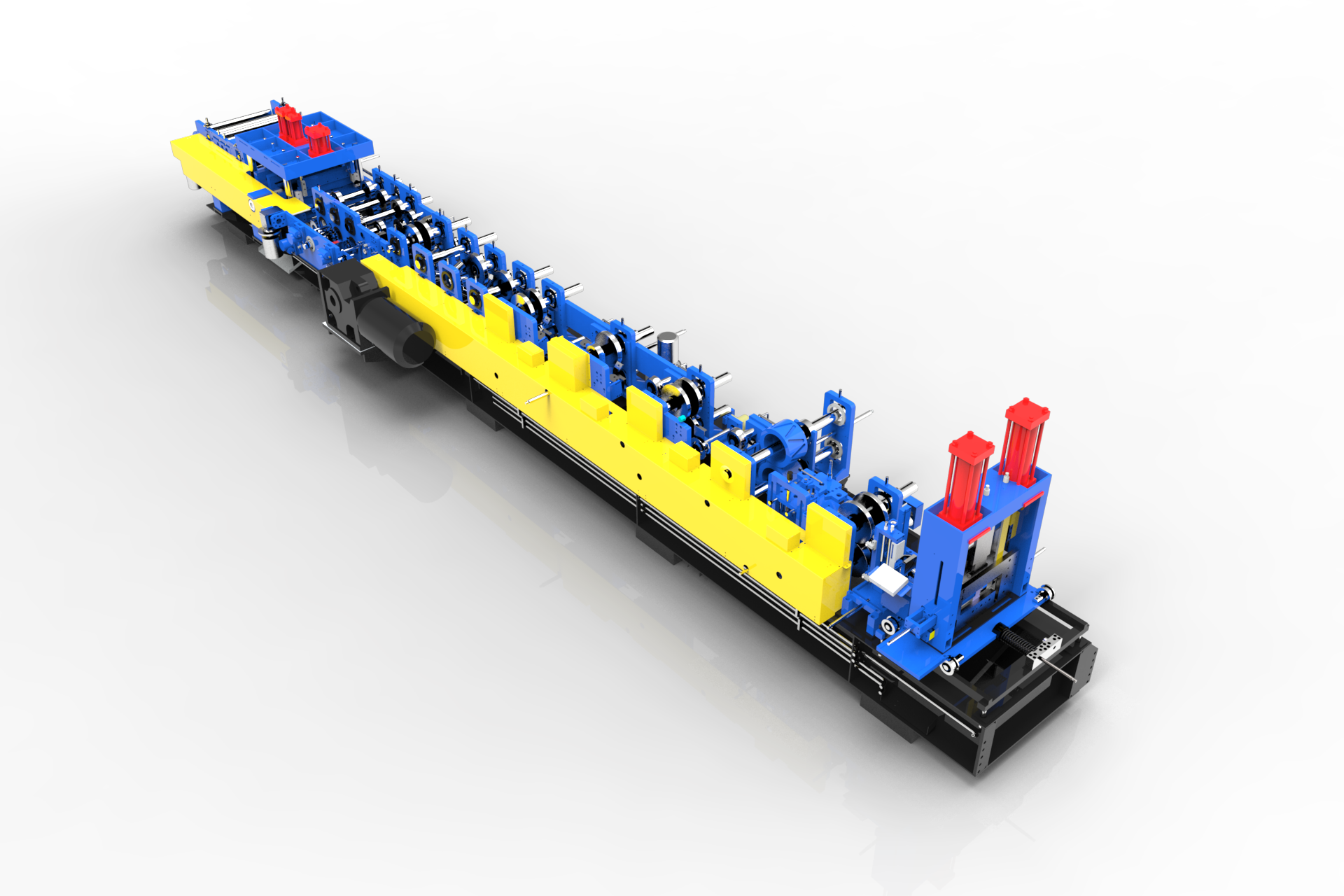

Gutter/Downspout roll forming machine by Metoform Technology

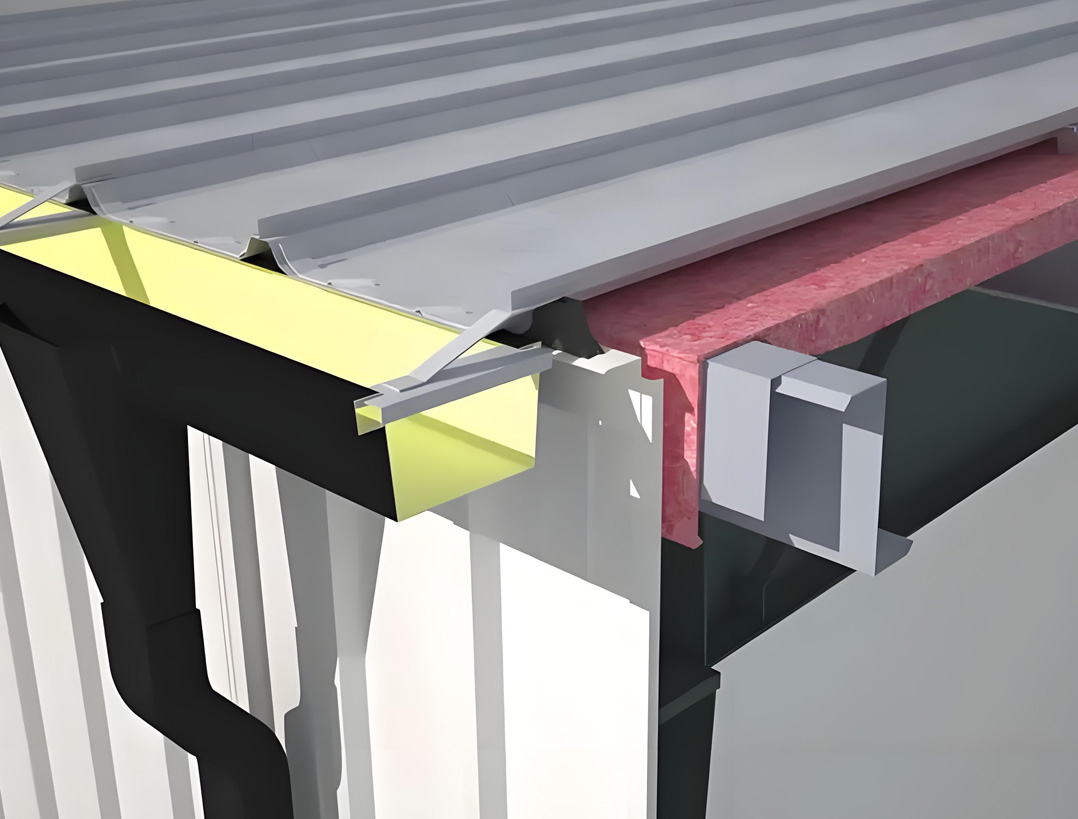

Gutters collect water from a large roof area, and downpipes channel it away from the building’s foundation.If without them, water would pour directly off the roof, saturating the ground around the foundation. By controlling the flow of water from the roof, the system prevents a concentrated deluge from washing away soil, damaging flower beds, and killing plants and grass directly next to the house. If without landscaping would be constantly battered and eroded by uncontrolled waterfall from the roof.

Gutters catch water and direct it to the downpipes, preventing it from running down exterior walls. By directing water away from the foundation, the system significantly reduces the amount of water that can seep into the basement through cracks or porous walls. They also protect Roof and Structural Integrity. In cold climates, gutters help channel melting snow away from the roof. While not a perfect solution, they are part of a system that includes proper attic insulation and ventilation to minimize ice dam formation.

High Efficiency & Speed

These machines can operate at speeds of 20 to over 48 meter per minute, producing vast quantities of panel in a single, uninterrupted run. This is orders of magnitude faster than manual fabrication or using press brakes

Superior Consistency & Quality

Every panel is identical with precise, repeatable dimensions.The progressive forming process, with multiple stations gradually shaping the metal, ensures that every inch of every panel has an identical cross-section. This is crucial for proper fit, installation, and structural integrity.

Material & Cost Savings

Dramatically reduces waste and lowers labor costs.

Using coiled metal is inherently more efficient than using pre-cut blanks, as it eliminates the skeleton waste typically generated when nesting parts on a sheet. This can lead to material utilization rates of over 95%.The high automation level translates to a lower cost per unit of production, as one operator can manage output that would require many more workers using traditional methods.

Flexibility and Design Advantages

Many machines are designed with quick-change roll technology, allowing producers to switch from producing one panel profile to another in minutes rather than hours. This makes short production runs economically viable.

Roll formers can be tooled to create unique, proprietary profiles for specific architectural, structural, or aesthetic applications, offering a competitive edge.

Applications

Downspouts (rainwater pipes) are used to collect rainwater from rooftops and drain it to the ground or sewer system through pipes. They are commonly found in residential buildings, public buildings, and industrial plants.

Gutters, a crucial component of rainwater collection systems, are installed between roof spans or in the eaves, directing rainwater to downspouts through a slope. They are suitable for industrial plants, large rooftops, and other applications.

Related Categories

Stay in touch with Metoform Technology

If you would like to learn more about Metoform Technology’s purlin roll forming machines, there are several ways to reach us. You can send an email to sales@metoform.com, give us a call at +86-592-8202880, or simply fill out the inquiry form on our website. Our team will get back to you as soon as possible to assist with your request.

Contact UsSign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.