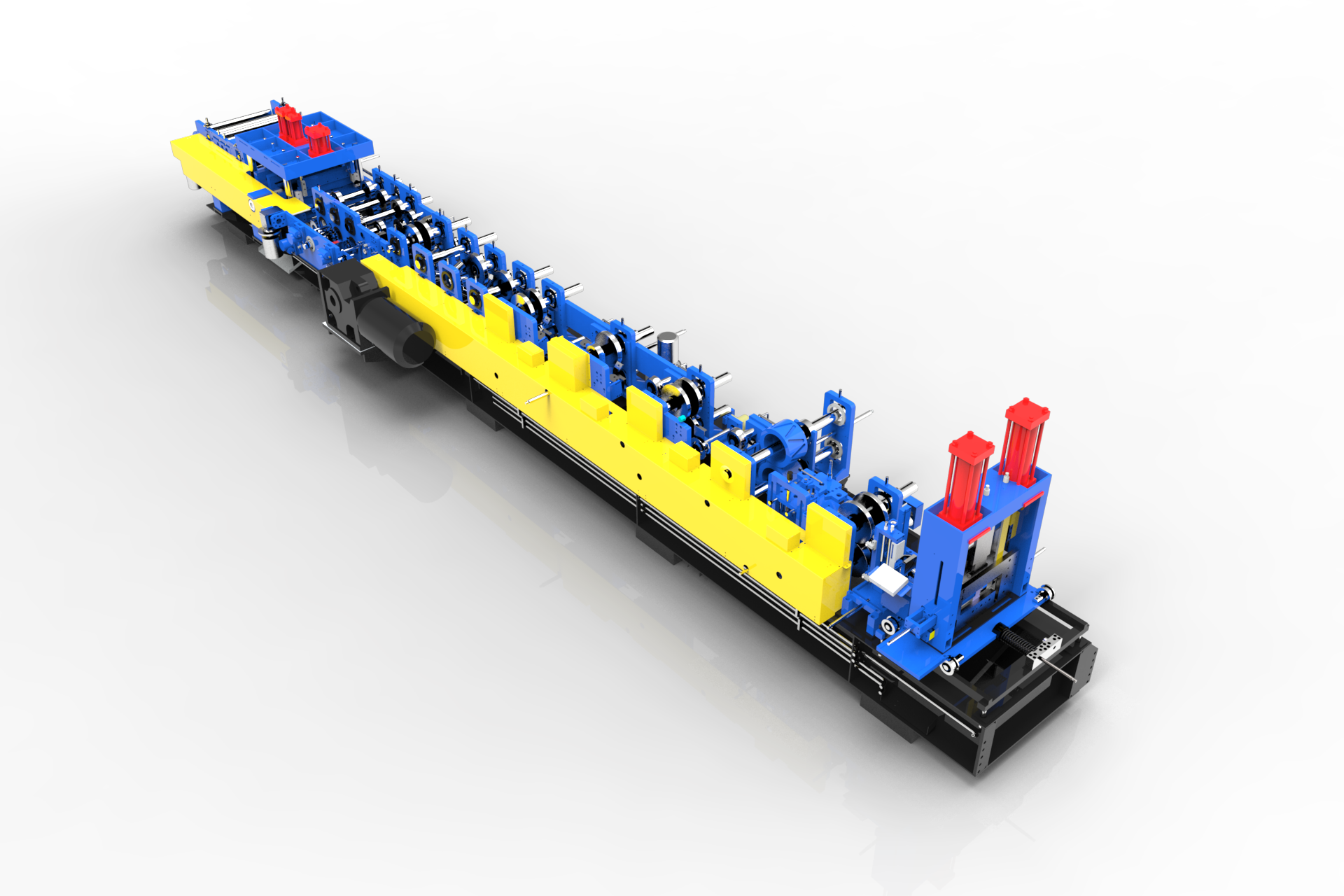

Purlin Roll Forming Machines by Metoform Technology

Metoform Technology provides a full range of purlin roll forming machines, including C purlin, Z purlin, and C/Z interchangeable models, as well as fully customized solutions. Whether your production requires standard profiles or specialized designs, our machines are engineered to deliver high precision and efficiency, meeting the diverse needs of steel structure manufacturing.

Built with advanced forming technology, our machines offer outstanding accuracy, durability, and ease of operation. Heavy-duty frames and quality components ensure long service life, while automated systems enable quick adjustments and flexible production. By reducing setup time, material waste, and labor costs, Metoform’s solutions give customers a competitive edge with greater efficiency and cost savings.

Widely applied in steel structure buildings, industrial warehouses, commercial complexes, residential projects, and large infrastructure, our purlin roll forming machines have become a trusted choice for global manufacturers. If you are looking for a reliable partner to upgrade your production line, contact Metoform Technology today for detailed specifications, tailored recommendations, and a customized quotation.

High Precision and Consistency

Precision-Engineered Rollers: Computer-designed and machined forming rollers ensure each purlin is formed to exact geometric specifications, batch after batch.

Minimal Material Deviation: This results in purlins with consistent dimensions, which is critical for easy and secure assembly on-site, reducing installation time and costs.

Exceptional Production Efficiency & Automation

High-Speed Operation: These machines can produce purlins at impressive speeds (e.g., 25-45 meters per minute), significantly outperforming manual or semi-automatic methods.

Integrated Automation: Features like automatic punching, notching, and cutting are synchronized with the rolling process. This creates a seamless, continuous production line from coil to finished product without manual intervention.

Significant Material Savings

Coil-to-Purlin Production: They use steel coils, which are more cost-effective than pre-cut sheets.

Optimized Cutting: The computer-controlled system (PLC) calculates the most efficient cutting lengths, drastically reducing material waste from off-cuts.

Versatility and Flexibility

Multiple Profiles: A single machine can typically produce various profiles (C-section, Z-section, U-section) and sizes simply by changing the set of rollers.

Easy Adjustability: Parameters like length, hole patterns, and flange width can be quickly programmed into the PLC, allowing for small, customized batches without downtime

User-Friendly Operation (The “English Version” Advantage)

Intuitive PLC/HMI Interface: The “English version” typically refers to a Human-Machine Interface (HMI) with software and menus in English. This makes it:

- Easier to Operate: Technicians can easily input commands, set parameters, and troubleshoot.

- Globally Accessible: English as the standard language simplifies operation for international teams and reduces language barriers during training and maintenance.

- Precise Control: Operators can fine-tune settings for speed, length, and punching patterns with clarity.

Robust Construction and Low Maintenance

Durable Components: Built with high-strength alloy steel rollers and a rigid frame to ensure stability and a long operational lifespan under continuous use.

Reliable Performance: Designed for 24/7 operation in industrial environments with minimal scheduled maintenance.

Enhanced Safety Features

Modern machines come equipped with safety guards, emergency stop buttons, and electrical protection systems to ensure operator safety.

Global Standard Compliance

These machines are built to produce purlins that meet international building codes and standards (e.g., CE, ISO), making them suitable for export-oriented manufacturing and global construction projects.

Summary of Benefits

In essence, an English-version purlin machine offers a powerful combination of speed, precision, and automation. It transforms raw steel coil into high-quality, ready-to-use structural components with minimal waste and labor. The English-language interface ensures that these advanced capabilities are accessible and manageable for operators worldwide, making it a smart investment for any metal fabrication business looking to improve efficiency and compete in the global market.

Comprehensive Model Options

Purlin roll forming machines by Metoform Technology are designed to deliver consistent quality and high precision in every profile. With models available for C purlins, Z purlins, and C/Z interchangeable systems, as well as customised solutions, our machines can meet the demands of both standard and complex production requirements.

Superior Performance & Efficiency

The advantages of our machines go beyond accuracy. They are built with heavy-duty frames and premium components for long-lasting durability, while smart automation and quick-change systems allow for faster setup and flexible production. This results in reduced labor, lower material waste, and greater cost efficiency for manufacturers.

Wide Applications & Business Value

Thanks to these benefits, purlin roll forming machines are widely used in steel structure buildings, warehouses, commercial facilities, residential projects, and infrastructure developments. If you are ready to enhance your productivity and profitability, reach out to Metoform Technology today for expert recommendations and a tailored quotation.

Applications

Industrial Buildings

Industrial Buildings C and Z purlins are the primary structural components for roofs and walls in large-scale factories, warehouses, and logistics centers. They provide essential support for the outer cladding and withstand environmental loads like wind and snow.

Commercial Buildings

Commercial Buildings Large-span commercial structures such as supermarkets, shopping malls, and stadiums utilize purlin systems to create wide, open spaces without internal columns. The lightweight yet strong nature of cold-formed purlins is ideal for these applications.

Agricultural Buildings

Agricultural Buildings Purlin machines are extensively used to produce components for agricultural structures like barns, grain storage sheds, livestock shelters, and greenhouses. They offer a cost-effective and rapid construction solution for the agricultural sector.

Other Structures and Uses

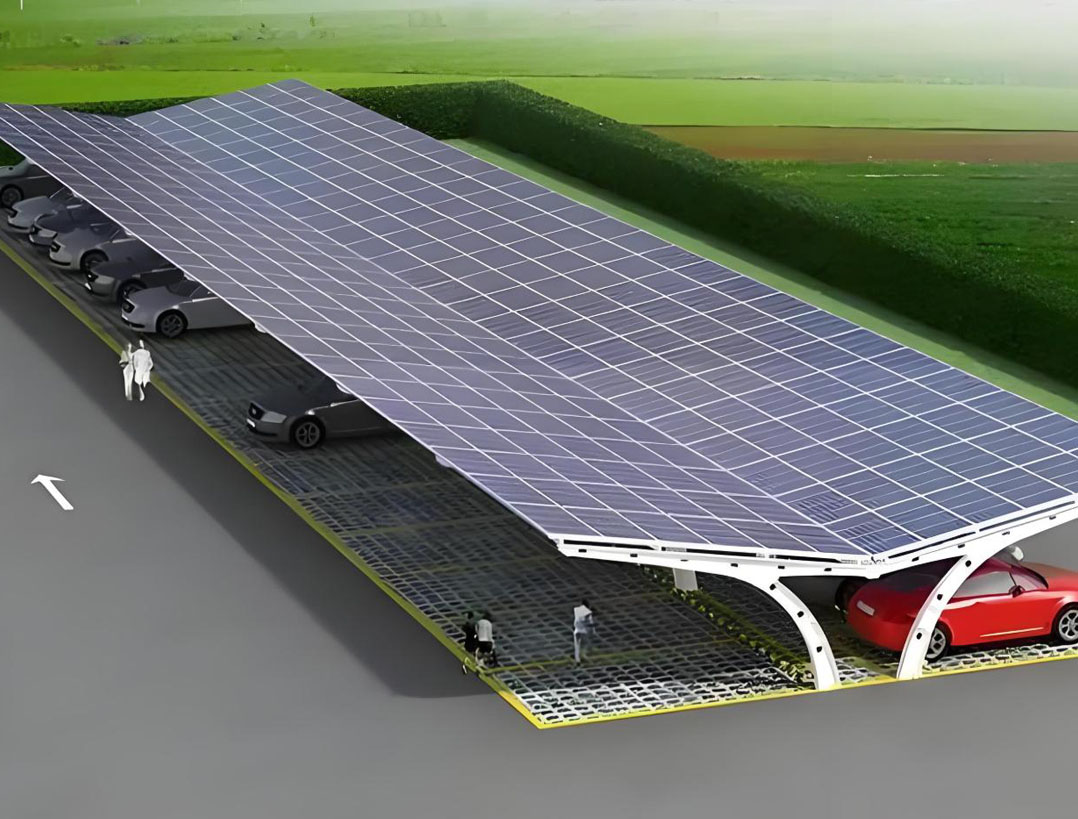

Solar Panel Mounting Systems Purlins are a fundamental component in the supporting structures for large-scale solar panel arrays. Their strength and ease of installation make them perfect for creating the framework that holds the solar panels at the optimal angle.

Related Categories

Stay in touch with Metoform Technology

If you would like to learn more about Metoform Technology’s purlin roll forming machines, there are several ways to reach us. You can send an email to sales@metoform.com, give us a call at +86-592-8202880, or simply fill out the inquiry form on our website. Our team will get back to you as soon as possible to assist with your request.

Contact UsSign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.