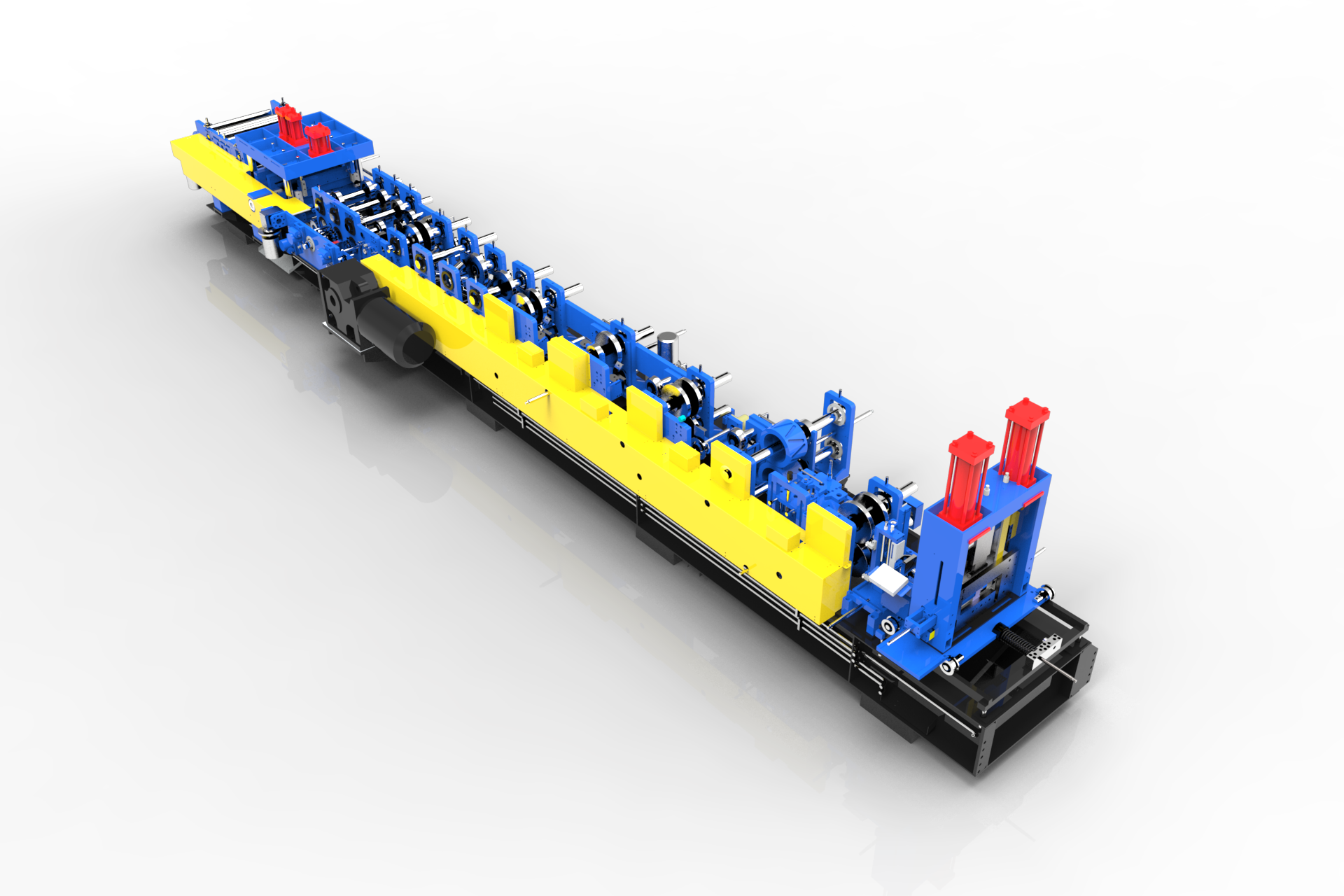

Roof and Wall Panel/Floor Decking Roll Forming Machine by Metoform Technology

This intelligent production solution for roof/wall/floor decking products covers multiple scenarios. The new generation of color-coated steel forming equipment includes a wide range of product lines, suitable for a variety of building materials, including glazed tile roof panels, corrugated profiles, standard roof and wall panels, and floor deckings.

Furthermore, the equipment supports fully customized production, allowing for flexible adjustments based on customer needs, enabling precise manufacturing of a wide range of specifications and models.

To ensure the industry’s leading quality, each new generation of color-coated steel forming machines undergoes a rigorous quality control system before shipment, encompassing comprehensive performance testing across various types of panels.

This comprehensive quality verification process ensures that each machine offers exceptional operational stability, superior processing accuracy, and reliable long-term performance, providing a solid foundation for color-coated steel production.

High Efficiency & Speed

These machines can operate at speeds of 20 to over 48 meter per minute, producing vast quantities of panel in a single, uninterrupted run. This is orders of magnitude faster than manual fabrication or using press brakes

Superior Consistency & Quality

Every panel is identical with precise, repeatable dimensions.The progressive forming process, with multiple stations gradually shaping the metal, ensures that every inch of every panel has an identical cross-section. This is crucial for proper fit, installation, and structural integrity.

Material & Cost Savings

Dramatically reduces waste and lowers labor costs.

Using coiled metal is inherently more efficient than using pre-cut blanks, as it eliminates the skeleton waste typically generated when nesting parts on a sheet. This can lead to material utilization rates of over 95%.The high automation level translates to a lower cost per unit of production, as one operator can manage output that would require many more workers using traditional methods.

Flexibility and Design Advantages

Many machines are designed with quick-change roll technology, allowing producers to switch from producing one panel profile to another in minutes rather than hours. This makes short production runs economically viable.

Roll formers can be tooled to create unique, proprietary profiles for specific architectural, structural, or aesthetic applications, offering a competitive edge.

Applications

Warehouses & Factories

Large, uninterrupted spans, entire building envelopes.

Agricultural Buildings

Barns, sheds, and stables; for sides and end walls.

Commercial Retail Units

Big-box stores, shopping centers. Curved facades are easily achieved.

Residential Homes

Modernist architecture or homes seeking a durable, low-maintenance roof.

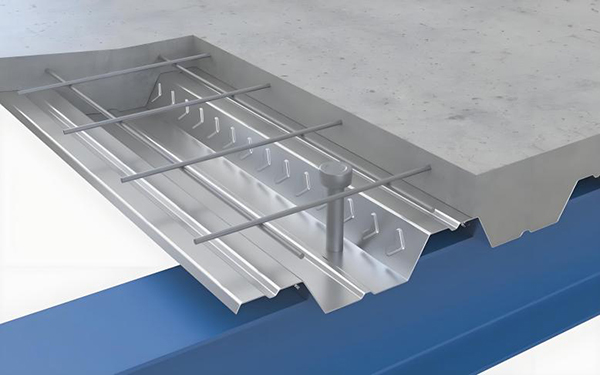

Multiple Applications in Steel Structure Buildings

This system meets the requirements for rapid construction of the main steel structure, providing a stable working platform in a short period of time. It also enables a continuous construction process where corrugated steel sheets are laid on multiple floors and concrete slabs are poured in layers.

Related Categories

Stay in touch with Metoform Technology

If you would like to learn more about Metoform Technology’s purlin roll forming machines, there are several ways to reach us. You can send an email to sales@metoform.com, give us a call at +86-592-8202880, or simply fill out the inquiry form on our website. Our team will get back to you as soon as possible to assist with your request.

Contact UsSign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.