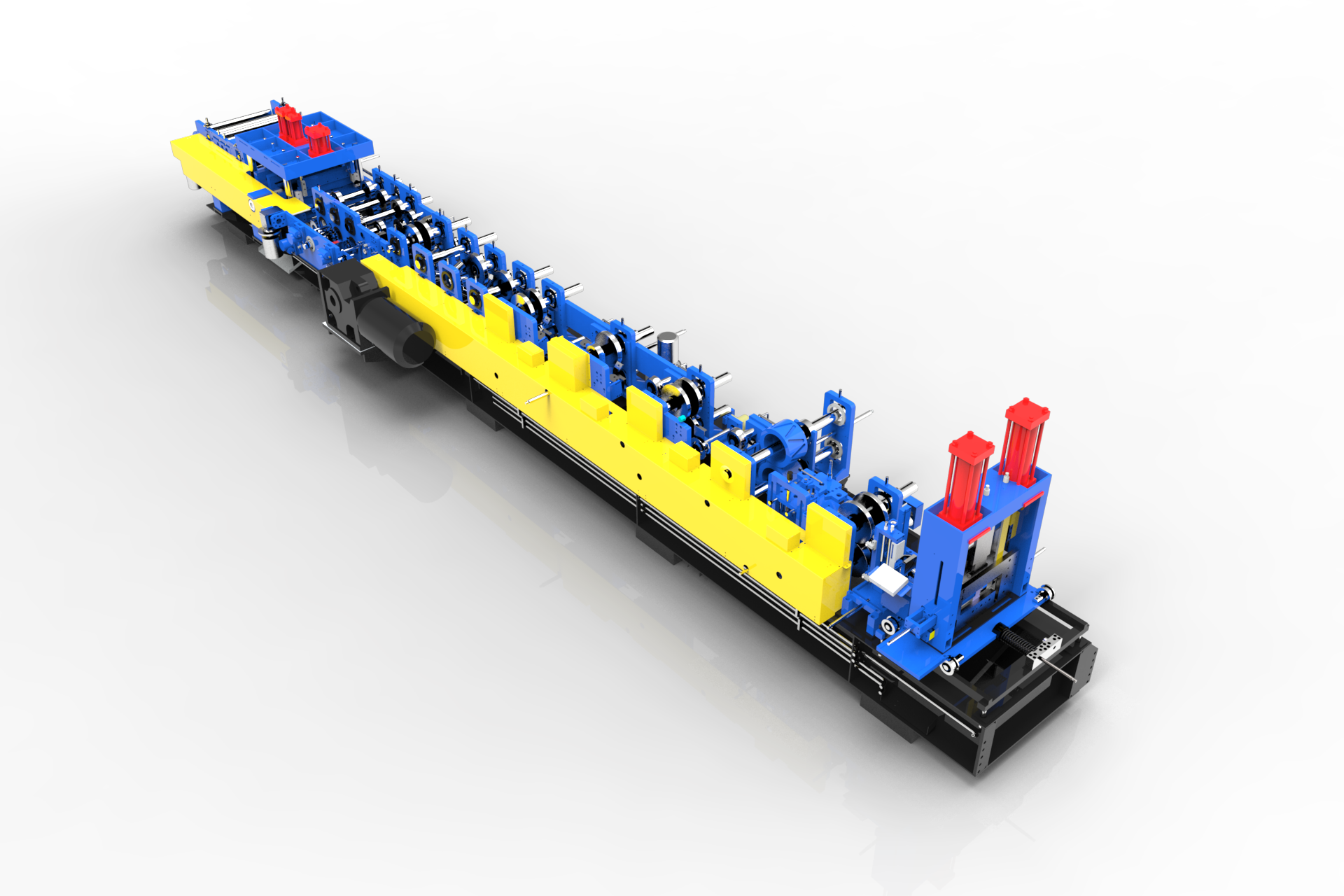

Light Gauge Steel Roll Framing Machine by Metoform Technology

Metoform Technology provides MULTI-SPECIFICATIONS Flexible Intelligent Manufacturing Machines. Integrating fast change cutting system, fully automated size change and control technology, the super light gauge steel roll forming machine features innovations

including back-to-back triangle truss, auto shrink&easy installation and through penetration, automatic gap adjustment and customized hole types, etc., and can produce products including CC, CU, easy installation and through penetration, grouting features, back-to-back trusses, floor joists, complex floors, special walls, and more.

One-click Size Change and Flexible Intelligent Manufacturing, Significant Upgrade in Production. Compatible with data from various design software.

Unmatched Precision and Consistency

Computer-Controlled: The machine is driven by CSV files. The design is directly translated into machine instructions, eliminating human error in measuring and cutting.

Tolerance: Components are produced with tolerances within fractions of a millimeter. Every stud, track, and joist is identical, which is impossible to achieve with manual fabrication or wood. This precision ensures that every component fits together perfectly on-site, drastically reducing installation time and problems.

Incredible Speed and Efficiency

High-Speed Production: 48m/min High speed productionA modern roll-forming line can produce one stud every few seconds. An entire frame for a house can be manufactured in a matter of days, not weeks.

Frames can be produced on-demand and shipped to the site exactly when needed, reducing storage costs and site clutter. The overall project timeline is significantly accelerated. The foundation can be prepared while the frame is being manufactured, leading to faster project completion.

Material Efficiency and Waste Reduction

Optimized Cutting: The software integrates components to maximize the use of the raw steel coil, minimizing off-cuts and scrap.

Predictable Ordering: Because the process is so precise, the amount of raw material needed can be calculated exactly, reducing over-ordering.

Versatility and Flexibility

Multiple Profiles: A single machine can typically produce various profiles (C-section, Z-section, U-section) and sizes simply by changing the set of rollers.

Easy Adjustability: Parameters like length, hole patterns, and flange width can be quickly programmed into the PLC, allowing for small, customized batches without downtime

Superior Strength and Durability

The machine can produce high-strength steel: The frames are made from galvanized or galvalume steel (typically G550/80KSi or AZ150), which is incredibly strong and resistant to bending, warping, and shrinking.

Reduced labor costs

Each machine requires only two skilled operators on site, reducing on-site labor costs.

Applications

Low-rise residential buildings (villas, self-built houses)

This is the most mature and widely used area for light steel structures. It’s particularly well-suited for residential applications requiring rapid construction, unique designs, or high environmental standards.

Application Features:

- Design Flexibility: Easily achieve a variety of modern, minimalist, or complex architectural styles.

- Comfort and Health: Walls are filled with insulation for excellent thermal insulation and energy efficiency. The non-toxic materials improve the living environment.

- Fast Construction: The main structure is assembled on-site like building blocks, minimizing weather impacts and requiring one-third to one-half the time of traditional construction.

Multi-Storey Apartments, Hotels, and Dormitories

Light steel structures are also suitable for multi-story buildings of 4-6 stories or even higher, such as talent housing, budget hotels, school dormitories, and nursing homes.

Application Features:

- High floor area efficiency: Wall thickness is thinner than that of brick-concrete structures, effectively increasing usable floor area.

- Industrialized Production: All components are prefabricated in the factory, ensuring quality control. Dry on-site construction reduces construction waste and is more environmentally friendly.

- Structural Safety: Excellent integrity and significantly superior seismic performance compared to brick-concrete structures.

Public Buildings and Commercial Facilities

Light steel structures are also commonly used in schools, kindergartens, hospitals, office buildings, exhibition halls, supermarkets, and more.

Application Features:

- Large-span spaces: Truss structures can create larger column-free spaces, meeting the functional requirements of public buildings.

- Fast Delivery: For projects that need to be operational quickly (such as emergency hospitals and schools), the rapid construction advantage is particularly evident.

Building Additions and Renovations

Application Features:

- Lightweight: Minimal load on existing structures and foundations, making it an ideal choice for rooftop additions, balcony expansions, and interior partitions.

- Low Construction Impact: Dry construction reduces noise and dust pollution, minimizing impact on building residents’ daily lives.

Modular Buildings and Container Homes

This is an advanced form of industrialized construction. Rooms or even entire building units are completely prefabricated in a factory, complete with interior finishes, and then transported to the site for immediate assembly and installation.

Application Features:

- Extremely Efficient: Only foundation work and hoisting are required on-site, resulting in extremely fast construction.

- Consistent Quality: The factory-based production environment ensures consistent and high-quality products.

- Mobility: Some modular buildings can be disassembled and rebuilt at a different location, resulting in a high degree of reuse.

Related Categories

Stay in touch with Metoform Technology

If you would like to learn more about Metoform Technology’s purlin roll forming machines, there are several ways to reach us. You can send an email to sales@metoform.com, give us a call at +86-592-8202880, or simply fill out the inquiry form on our website. Our team will get back to you as soon as possible to assist with your request.

Contact UsSign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.