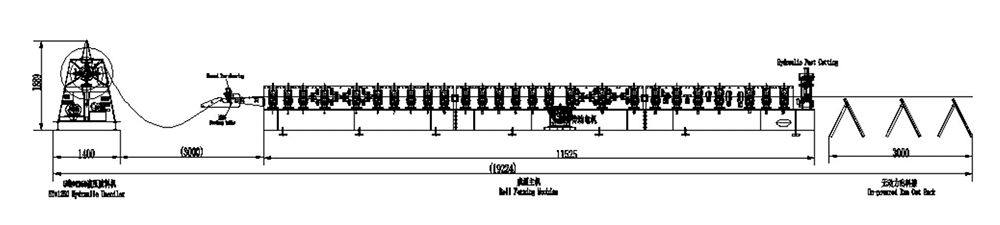

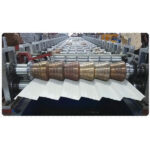

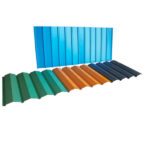

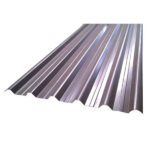

Corrugated roll forming machine is a continuous, high-volume production system designed to transform a flat sheet of metal (typically steel or aluminum) into a corrugated profile.

It does this by progressively bending the metal through a series of paired rolls, called stations or stands, until the desired wave-like shape is achieved. It is the primary piece of equipment used in the manufacturing of corrugated metal roofing and siding panels.