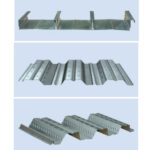

Floor decking machine is a specialised piece of construction equipment used to automate the placement and fastening of metal floor decking (profiled steel sheets) onto the structural steel frame of a building.

Its primary purpose is to significantly increase the speed, safety, and efficiency of constructing composite floors in multi-story buildings like offices, apartments, hospitals, and hotels.