Sheet Metal Forming: A Comprehensive Guide to Techniques and Applications

Sheet metal forming is a crucial manufacturing process that shapes flat metal sheets into complex components used in a wide range of industries. This versatile technique allows manufacturers to produce lightweight, durable, and precise parts.

Whether it’s for automotive bodies, electronics enclosures, or structural components, sheet metal forming is essential in modern production.

This blog provides an in-depth look at the different types of sheet metal forming processes, the equipment involved, their applications, and the challenges faced in this manufacturing method.

What Is Sheet Metal Forming?

Sheet metal forming refers to a group of processes that use mechanical force to reshape flat metal sheets into desired shapes without removing material. Instead of cutting away metal, as in machining processes, forming works by stretching, bending, or compressing the metal.

Typically, sheets range in thickness from 0.006 inches to 0.25 inches, and materials commonly used include aluminum, steel, copper, and brass. Sheet metal forming provides excellent strength-to-weight ratios, making it ideal for industries where lightweight yet strong components are essential.

Key Sheet Metal Forming Processes

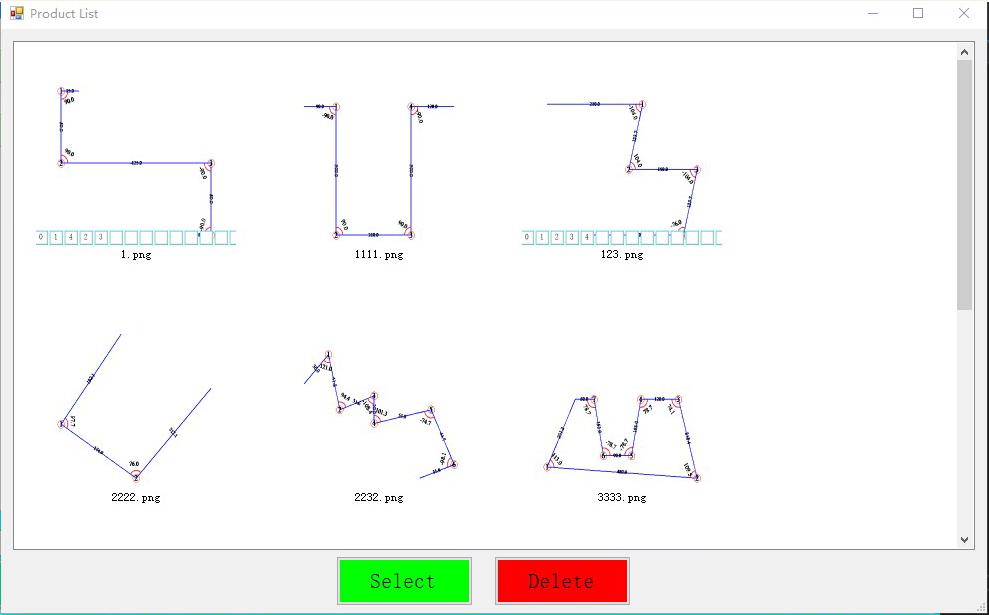

Sheet metal forming is a broad term that encompasses various techniques, each with its own set of advantages depending on the specific application. Some of the most common methods include bending, stamping, deep drawing, roll forming, and stretch forming.

Bending

Bending is one of the most common sheet metal forming processes. It involves applying force to a metal sheet to create a permanent bend along a straight axis. The process is often performed using press brakes, which apply pressure to the sheet metal, causing it to bend at a specific angle. This technique is widely used for producing items like brackets, enclosures, and chassis.

Stamping

Stamping is a broad category of processes, including punching, blanking, and embossing, used to form metal sheets into specific shapes.

A stamping press uses dies and punches to apply pressure to the metal, producing parts with precise shapes. Stamping is particularly useful for high-volume production of automotive body panels, appliance components, and other metal parts.

Deep Drawing

Deep drawing is a process where a flat sheet of metal is drawn into a die by a punch, forming deep or hollow shapes. This technique is commonly used to produce products like sink basins, cooking pots, and fuel tanks. Hydraulic presses are typically used for deep drawing, as they can provide the necessary force to draw the metal without tearing.

Roll Forming

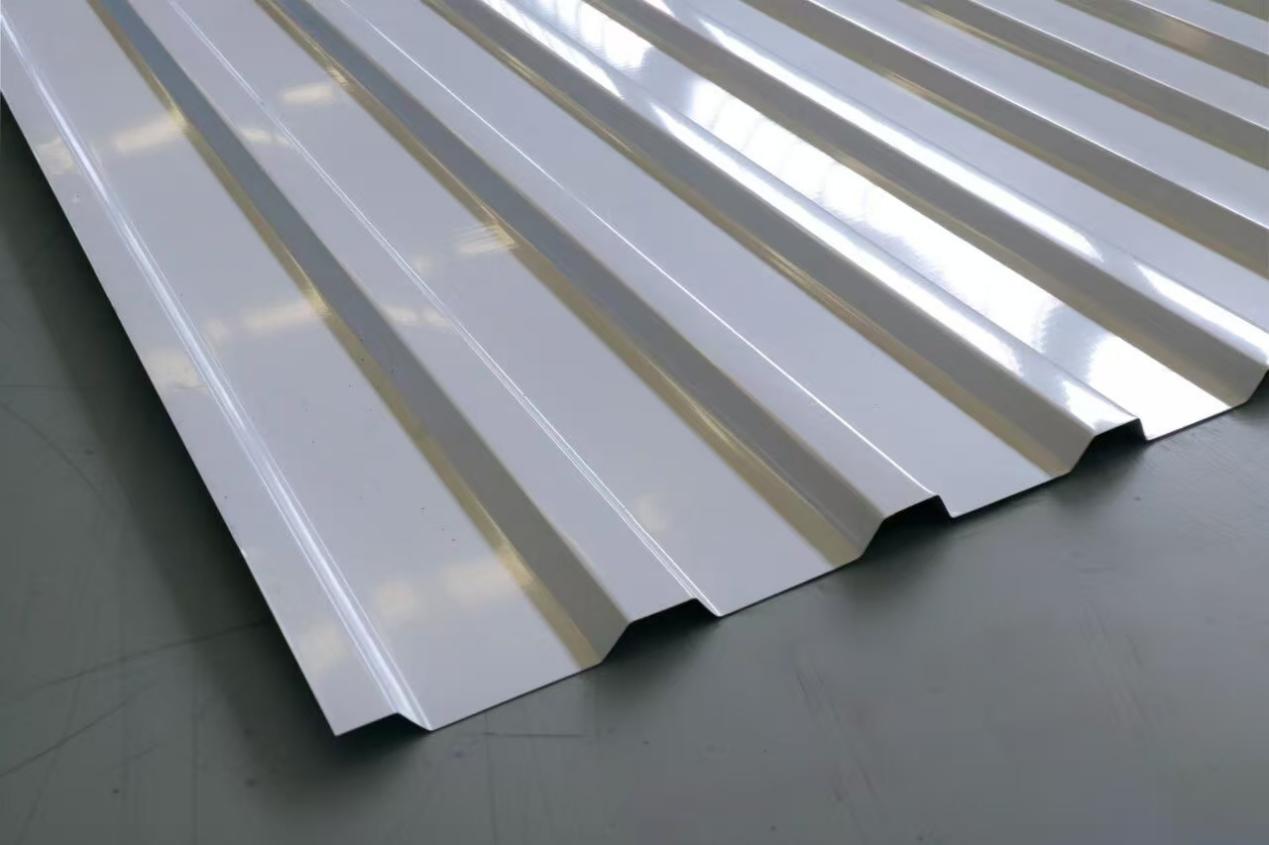

Roll forming is a continuous process that passes a metal sheet through a series of rollers to gradually shape it into the desired profile.

This method is ideal for producing long parts with consistent cross-sections, such as roofing panels, structural components, and channel sections. Roll forming is highly efficient and produces parts with a uniform profile.

Stretch Forming

Stretch forming involves stretching a metal sheet over a form to create a desired shape, often used to create large contoured parts.

This process is commonly used in the aerospace industry to produce complex, curved panels for aircraft bodies. The process requires careful control of tension and temperature to avoid material failure.

Essential Equipment in Sheet Metal Forming

The choice of equipment in sheet metal forming depends on the specific process and production requirements.

Key machines include:

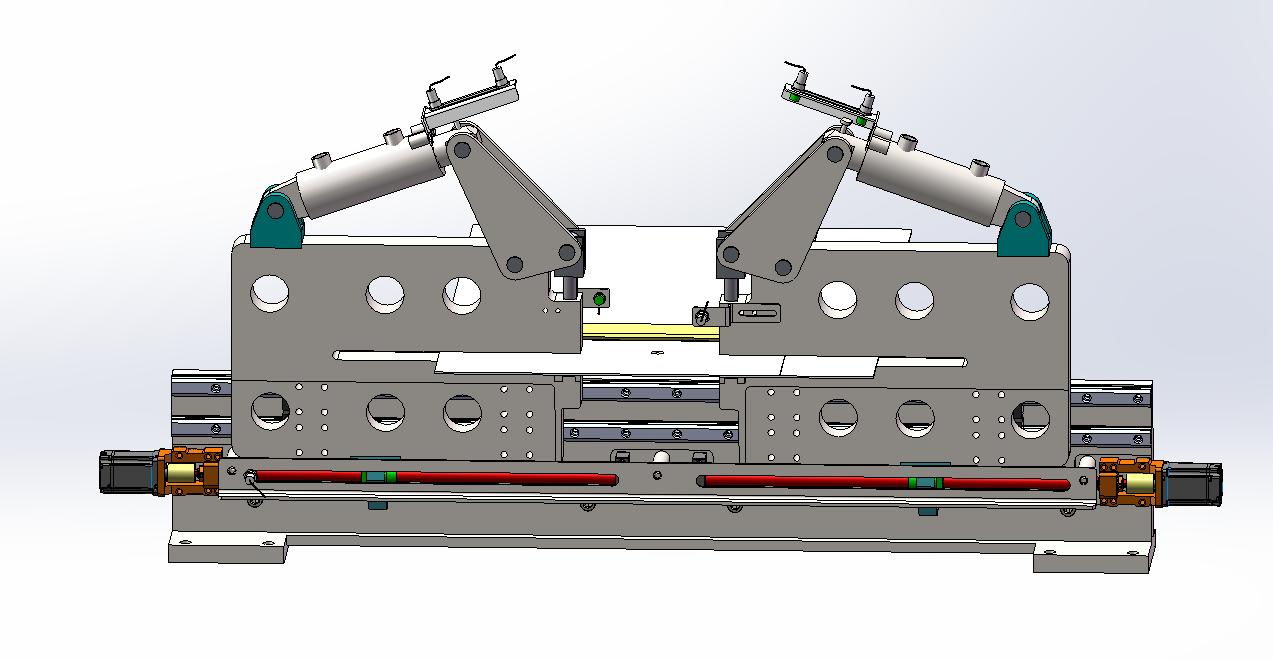

Press Brakes: Used for bending operations, press brakes apply force to a punch that deforms the metal sheet over a die.

Stamping Presses: These machines use dies and punches to cut, shape, or form metal sheets in stamping operations.

Roll Forming Machines: Utilise a series of rollers to gradually shape metal sheets into desired profiles.

Hydraulic Presses: Employ hydraulic force to perform operations like deep drawing and stretch forming.

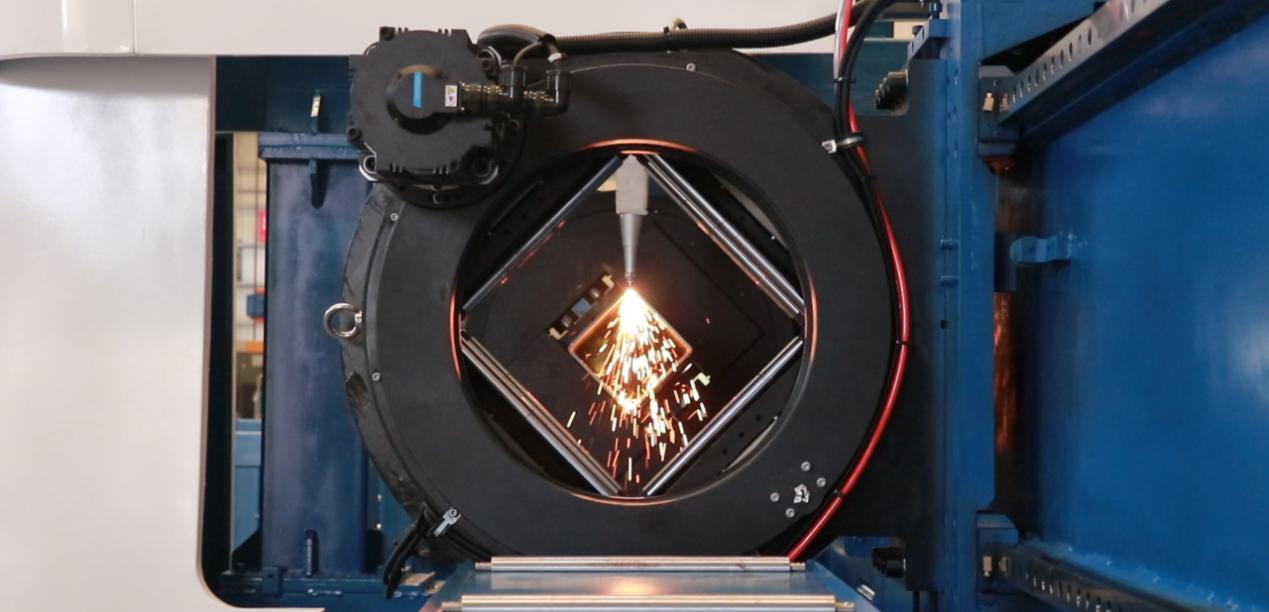

Laser Cutting Machines: Use focused laser beams to cut metal sheets with high precision, ideal for intricate designs.

Advancements in automation and computer numerical control (CNC) have enhanced the precision and efficiency of these machines, enabling complex geometries and high-volume production.

Applications of Sheet Metal Forming

Sheet metal forming is widely used across many industries, from automotive to electronics, thanks to its versatility and cost-effectiveness. In the automotive industry, sheet metal forming is essential for producing body panels, chassis, and structural parts that require strength, durability, and lightweight characteristics.

The aerospace industry relies on sheet metal forming for aircraft skins, brackets, and other components that must meet strict performance standards while maintaining weight efficiency.

In electronics, sheet metal is used for creating enclosures that protect sensitive components. This includes everything from computer cases to housings for medical devices and consumer electronics.

The construction industry also benefits from sheet metal forming, using it to produce roofing panels, ducts, and framing components. Even in the consumer goods industry, sheet metal forming plays a role in producing kitchenware, appliance housings, and decorative elements.

Advantages of Sheet Metal Forming

Material Efficiency: Minimises material waste by utilising the full sheet, making it cost-effective for large-scale production.

Strength and Durability: Produces parts with high strength-to-weight ratios, essential for structural applications.

Design Flexibility: Accommodates complex shapes and designs, enabling innovation in product development.

High Production Rates: Processes like stamping and roll forming allow for rapid manufacturing of parts.

Consistency and Precision: Advanced equipment ensures tight tolerances and uniformity across large production runs.

Challenges in Sheet Metal Forming

While sheet metal forming offers numerous advantages, it also comes with its challenges. One of the primary concerns is material limitations. Some metals may be difficult to form due to their thickness, hardness, or ductility.

For example, materials that are too thick may be prone to cracking during forming, while materials that are too thin may not provide the necessary strength for certain applications.

Another challenge in sheet metal forming is the cost of tooling, especially for custom designs. Creating dies and molds for specific parts can be a significant upfront cost, which can impact the overall profitability of smaller production runs.

Additionally, the issue of springback, where materials slightly return to their original shape after bending, can cause inaccuracies in the final product unless properly accounted for during the design phase.

Lastly, there are forming limits associated with the amount of deformation a material can withstand. Excessive stretching or bending can lead to material failure, so it is crucial to control process parameters like temperature, force, and speed carefully.

Future Trends in Sheet Metal Forming

The sheet metal forming industry is evolving with advancements in technology, including:

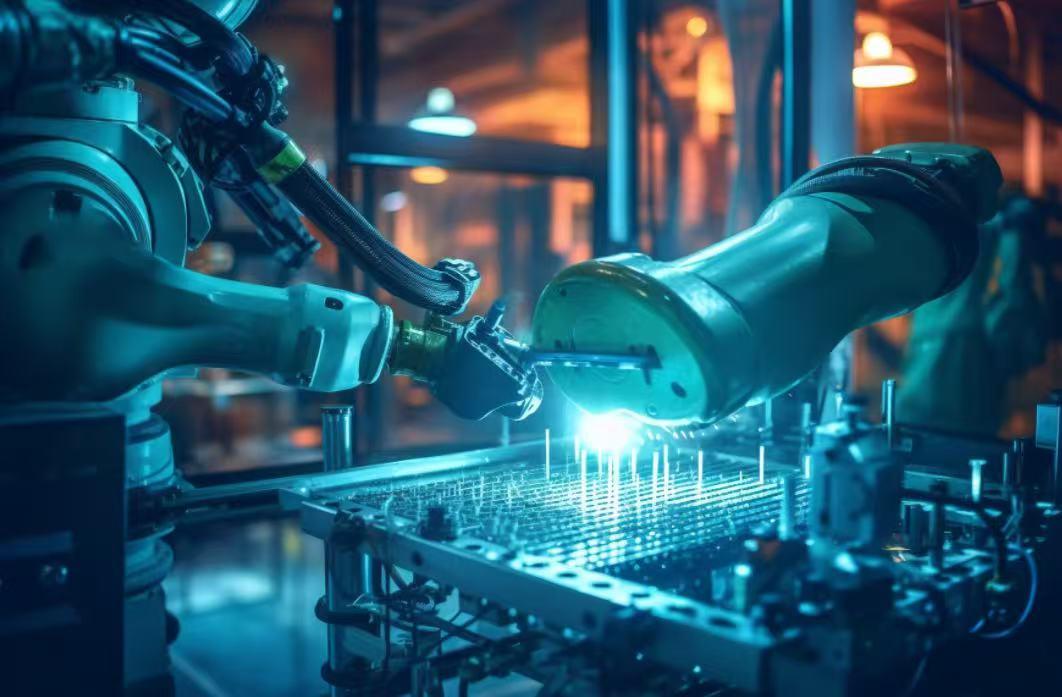

Automation and Robotics: Integration of automated systems for material handling and part production to increase efficiency and reduce labor costs.

Additive Manufacturing: Use of 3D printing techniques to create complex tooling and prototypes for sheet metal forming processes.

Advanced Materials: Development of new alloys and composites that offer improved performance and formability.

Sustainability Initiatives: Focus on reducing energy consumption, material waste, and environmental impact through optimised processes and recycling efforts.

These innovations are shaping the future of sheet metal forming, enabling more efficient, sustainable, and precise manufacturing practices.

Conclusion

Sheet metal forming remains an essential process in modern manufacturing, providing a wide range of industries with the ability to create strong, precise, and cost-effective parts.

From bending and deep drawing to advanced techniques like roll forming and stretch forming, the flexibility of sheet metal forming allows manufacturers to meet the growing demands of various industries, including automotive, aerospace, electronics, and construction.

While there are challenges in terms of material selection, tooling costs, and precision, advancements in technology are addressing many of these issues, making sheet metal forming more efficient and sustainable.

As the industry continues to evolve, sheet metal forming will undoubtedly play an even more critical role in shaping the future of manufacturing.

Product Recommendation

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.