In the rapidly evolving field of warehousing and logistics and industrial racking systems, the demand for efficient, high-quality production equipment is unprecedented. Shelf roll forming machines have become essential equipment for many racking manufacturers.

This article will delve into the working principles, value, market trends, and maintenance of shelf roll forming machines. It will also cover how to select the right equipment for your operations and how to ensure its long-term stable operation.

What is a Storage Rack Roll Forming Machine?

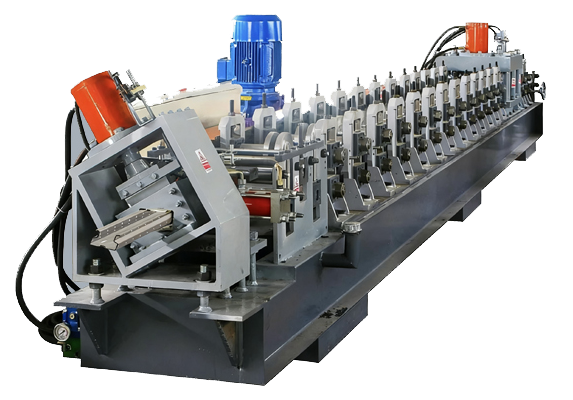

A warehouse racking roll forming machine is a specialized production line. It is primarily used to process flat metal coils or sheets into precision profiles for warehouse racking, racking systems, uprights, beams, support rods, and other support components.

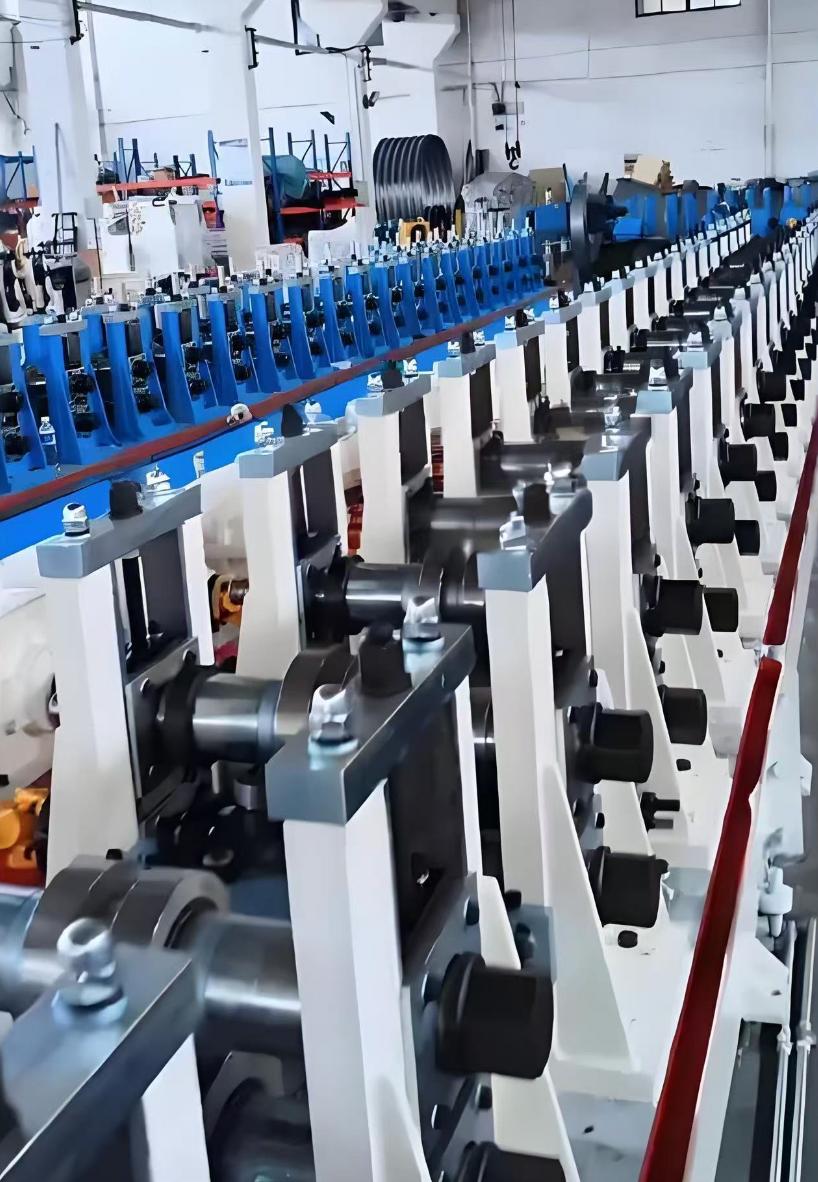

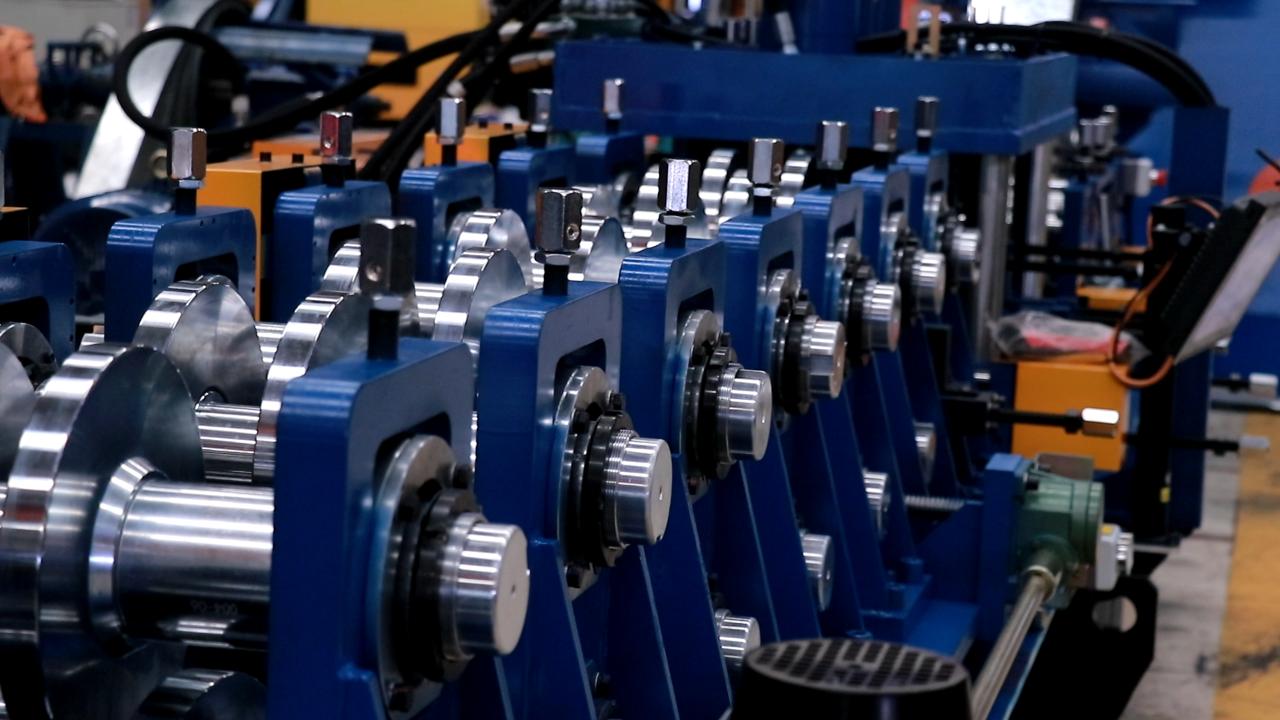

The machine typically includes an uncoiler, a leveling/straightening device, a servo feeder, punching or grooving stations, a roll forming frame, a cutting unit, and often an automated stacker or unloading platform.