Precision Engineering for Diverse Applications

Metoform specializes in high-precision roll forming machines designed to meet the evolving needs of the construction and manufacturing industries. With over 15 years of experience and more than 63 R&D patents, we provide innovative solutions for a wide range of applications.

PRODUCT CATEGORY

How Roll Forming Works?

Roll forming is a progressive machining process where a flat metal strip is transformed into a finished part or profile. The material is passed through a series of powered rollers, each step gradually shaping the material into its final form. The process typically starts with a metal coil, and the final product length is based on specific production requirements.

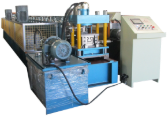

Complete Roll Forming Production Lines

Metoform’s roll forming machines are designed to include all necessary processes for producing finished products, such as feeding, roll forming, punching, and bending. These technologies are seamlessly integrated to maximize efficiency and performance.

Our advanced systems also feature automation for assembly and in-line packaging. Each production line is engineered to ensure compatibility, resulting in smooth operation and optimal results.

Metoform Roll Forming Machines for Every Need

Metoform’s roll forming machines are designed to cater to a wide array of applications:

- MF Series: Perfect for light gauge material, used in residential and commercial construction.

- Heavy-Duty Roll Formers: Built for industrial applications, capable of processing thicker metals.

- Custom Roll Formers: Tailored solutions for complex and unique production requirements.

Specialization in Thin Gauge Materials

With over 15 years of expertise, Metoform is a leader in roll forming machines for thin gauge materials. Our machines are designed to provide high-quality output for light gauge sheet metal, ideal for industries such as construction, automotive, and manufacturing.

Whether you’re working with steel, aluminum, or other metals, Metoform’s machines ensure consistent quality across a range of profiles and materials.

Contact us

For more information or to request a quote, please contact us. Our team is ready to assist you in selecting the right solution for your project needs.

Advanced Technology & Customization

Metoform’s machines incorporate the latest technology to ensure precision and efficiency. We offer customization options to meet specific project requirements, including:

Sign Up For Our Newsletter

Subscribe to our newsletter for product promos, news, and more.