A Storage Rack Roll Forming Machine is a highly specialized, continuous manufacturing system that transforms raw steel coils into the critical structural components of industrial storage racking systems. It is the core piece of equipment in a rack manufacturing plant, automating a process that would be incredibly slow, inconsistent, and costly if done by other methods.

The machine’s primary function is to take a flat strip of steel (from a coil) and progressively shape it, through a series of roller dies, into a specific, complex cross-sectional profile.

The main outputs are:

- Upright Frames: The vertical columns that form the backbone of the rack system. These have a complex profile with perforations (for beam connection) and stiffening ridges.

- Beam Profiles: The horizontal arms upon which pallets or goods are placed.

- Bracing Struts: The diagonal or horizontal members that connect uprights for stability.

Main Components

| Hydraulic Decoiler with Pre-leveling device | Holds and feeds steel coils smoothly into the line. |

| Roller feeder by a Servo motor | |

| 110T Press | |

| Roll Forming Machine | Precision-engineered rollers shape steel into into different profiles with accuracy. |

| Hydraulic Flying Cutting System with pin-insert design | Provides fast, clean, and burr-free cuts to required lengths. |

| Output Table with pneumatic un-loading function | User-friendly interface for automatic operation and easy adjustments. |

| Control System (PLC + Touch Screen) | Collects finished products for efficient handling and packaging. |

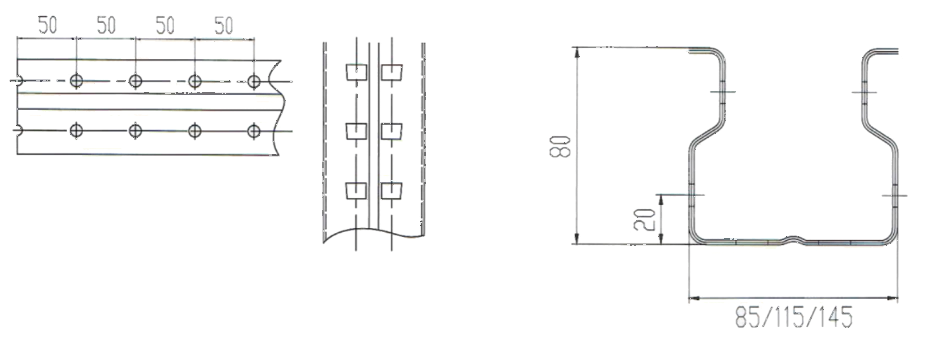

Drawing

Key Features

- High Efficiency & Output: Continuous operation allows for mass production, essential for meeting market demand.

- Exceptional Consistency & Quality: Every piece is identical, ensuring the structural integrity and interchangeability of the rack components.

- Material Efficiency: Virtually no material waste compared to other forming methods.

- Strength Enhancement: The cold-working process of roll forming can slightly increase the strength of the steel. The complex profiles themselves are engineered for maximum load-bearing capacity with minimal weight.

- Integration: Seamlessly integrates pre-punching and cutting, creating a finished or near-finished product in a single pass.

Technical Specifications

| Material | Type | GI,cold-rolled steel |

| Thickness(mm) | 1.5-4.0 | |

| Yield Strength(Mpa) | 230-350 | |

| Forming Speed(m/min) | 15-45 | |

| Roller Station | Depends | |

| Roller Material | Cr12 steel with hard chrome treatment | |

| Roller Driven Type | Chain transmission/Gearbox | |

| Shaft Material | 45# steel with heat treatment | |

| Shaft Diameter | Ø80-90 mm | |

| Control System | PLC+Touch screen and button | |

| Main Machine Power(KW) | 15-30(or customized) | |

| Hydraulic station Power(KW) | 7.5 | |

| Machine Weight(Kg) | 10500 | |

| Machine size(m) | 10.5×1.8×1.9 Depend on final design | |