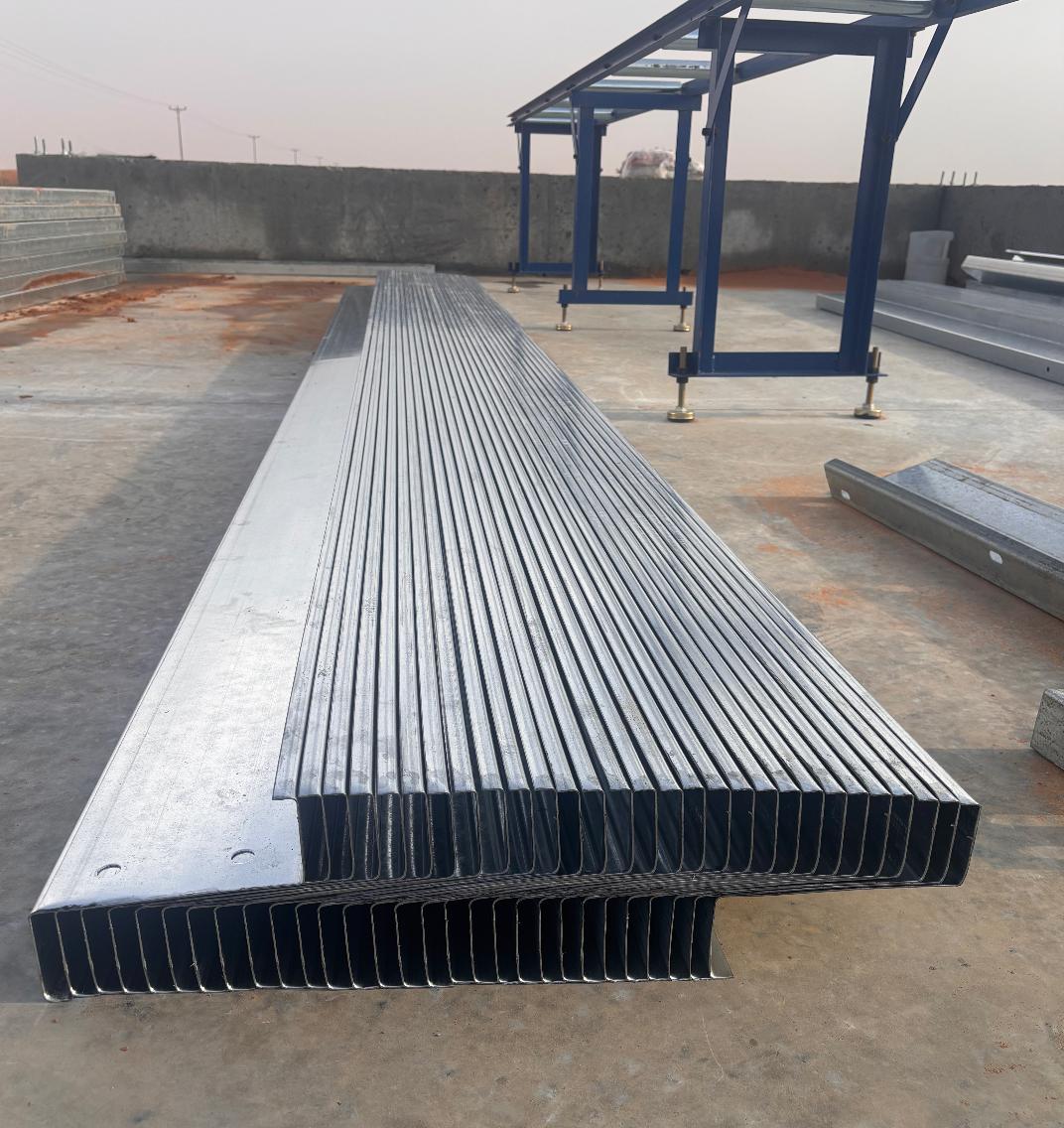

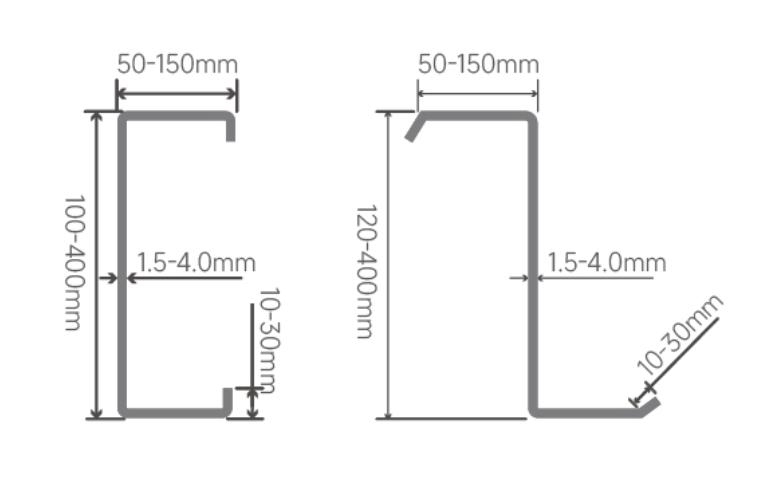

In modern steel construction, purlins are essential structural components that support roof and wall systems. As demand for pre-engineered buildings, industrial facilities, solar structures, and light-gauge steel framing continues to grow, manufacturers face increasing pressure to produce multiple purlin profiles efficiently and consistently.

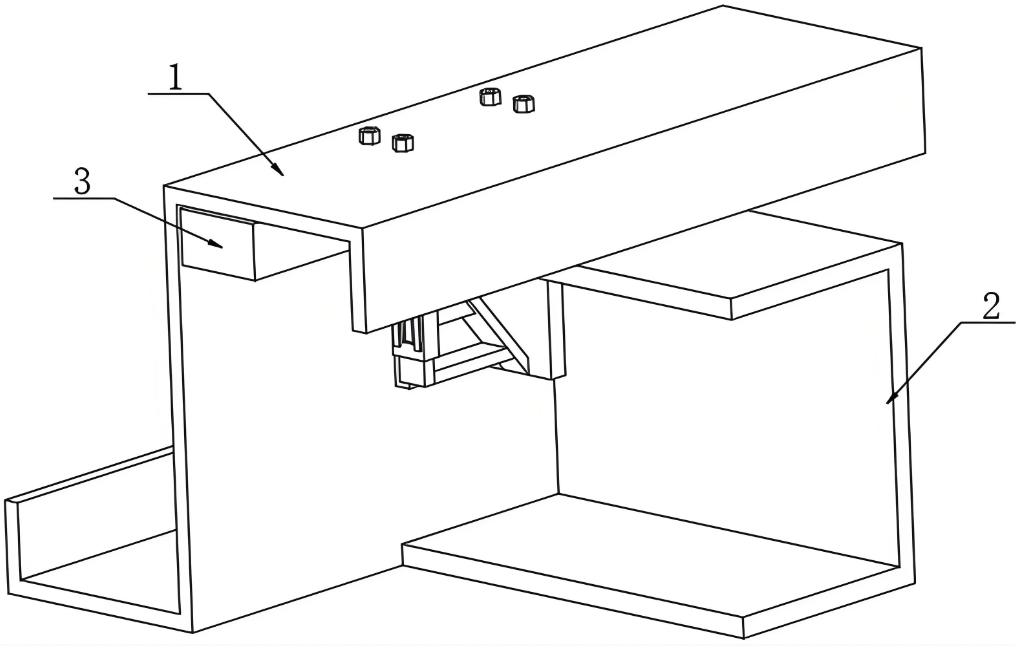

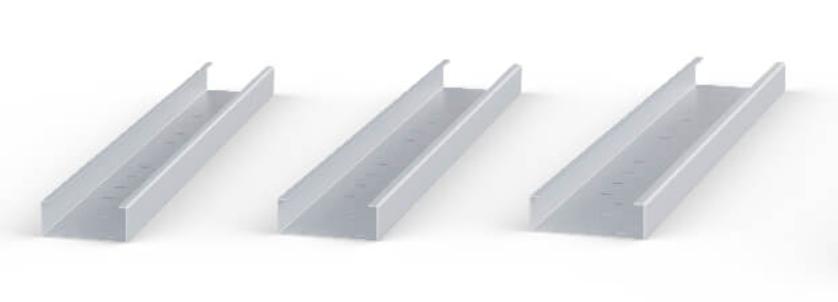

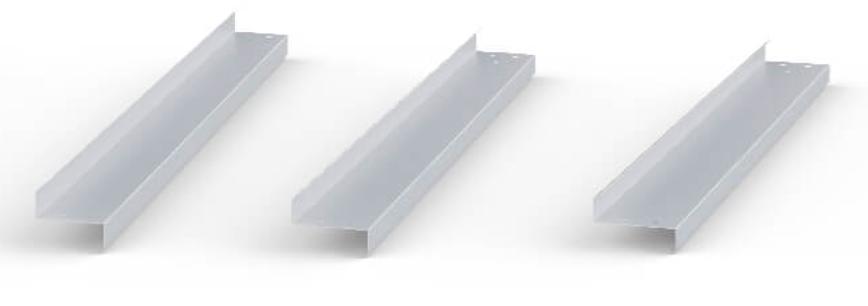

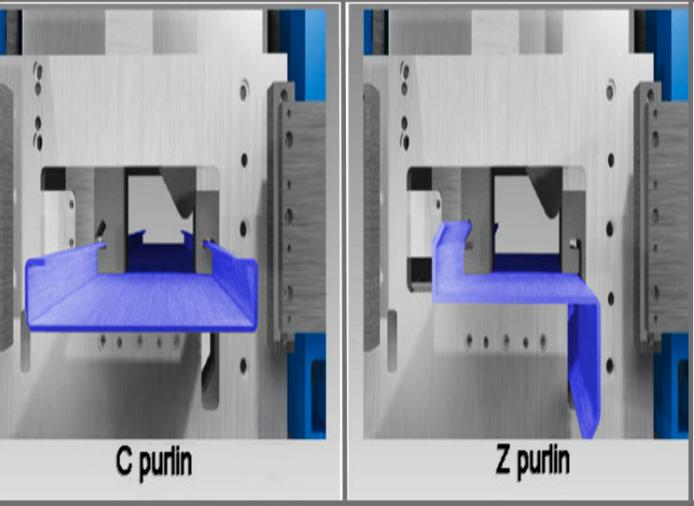

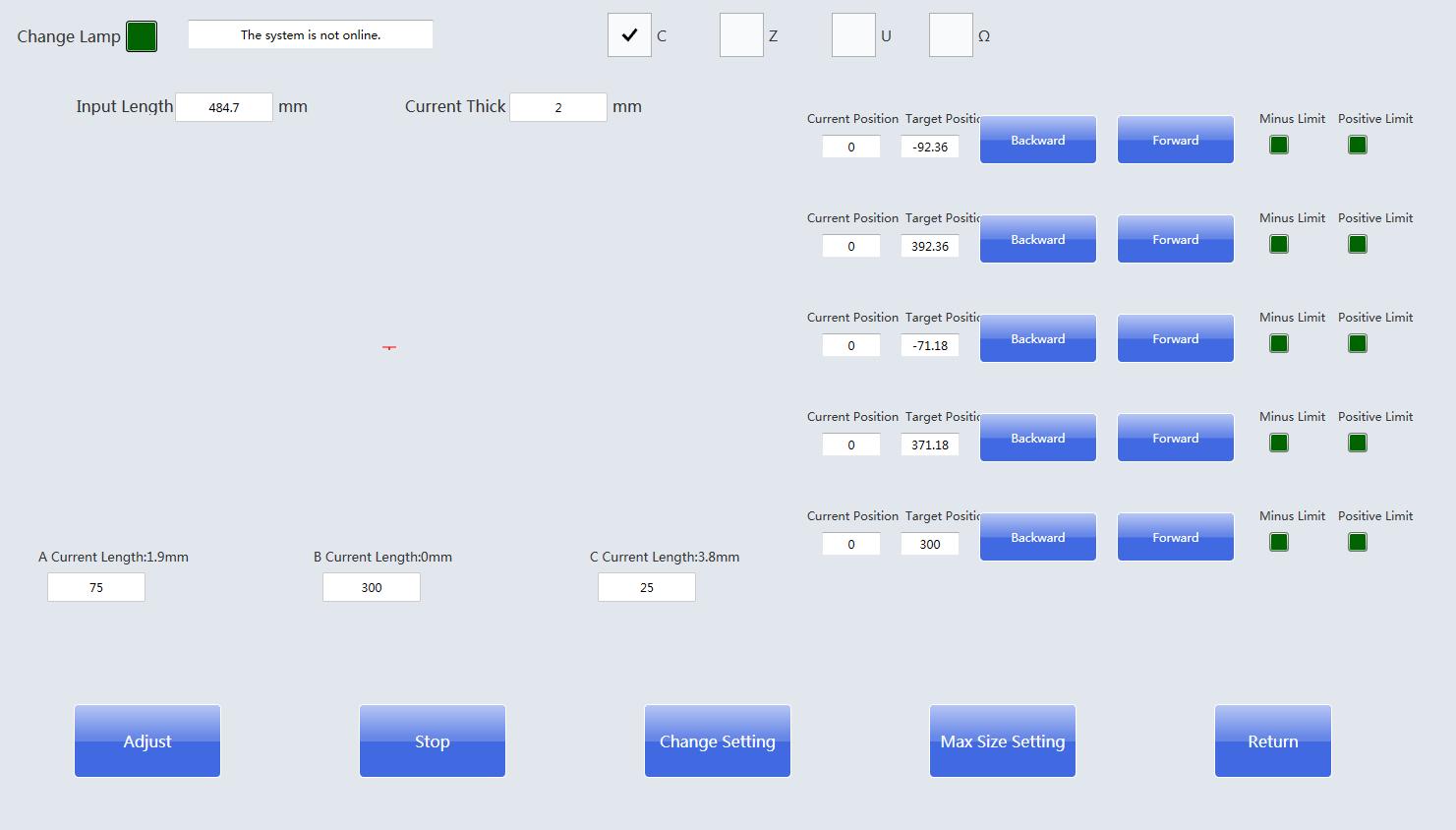

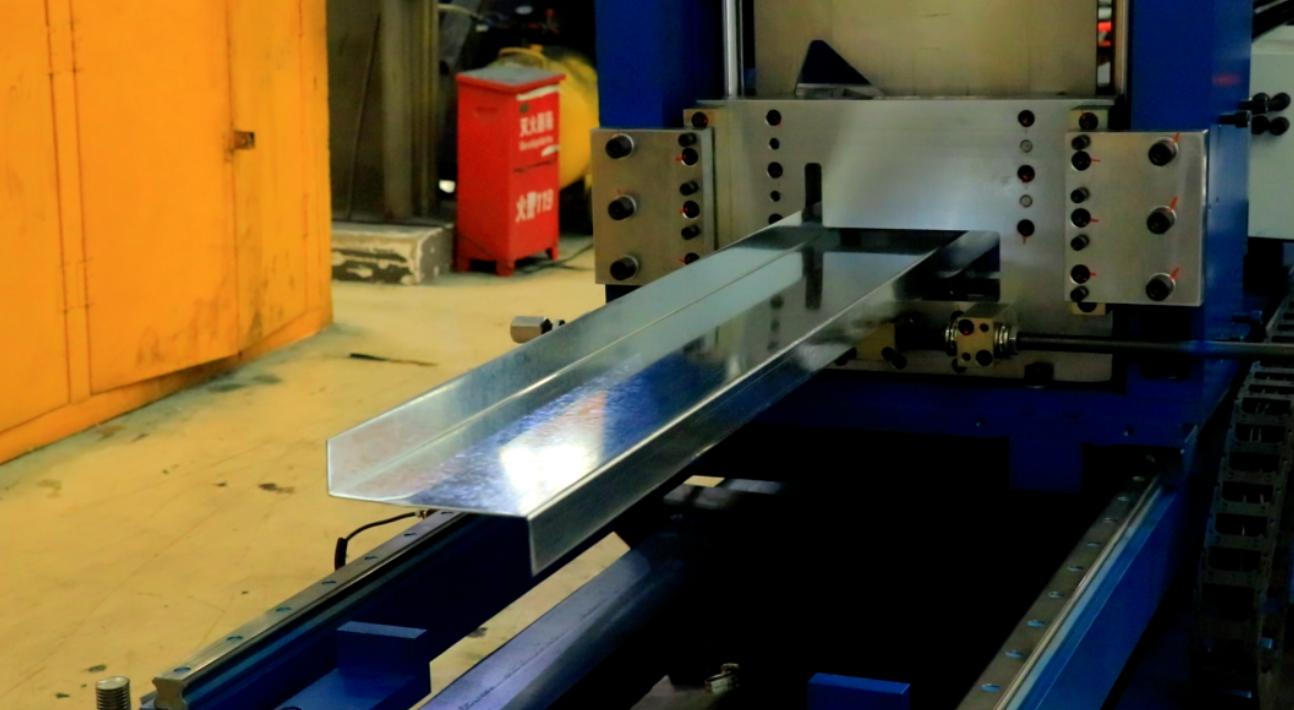

C-purlins and Z-purlins remain the most commonly specified profiles, each serving different structural and installation requirements. Traditionally, these profiles have been produced on separate roll forming machines. However, advances in roll forming technology have led to the widespread adoption of CZ interchangeable purlin machines, which allow manufacturers to produce both profiles on a single production line.

This article provides a detailed comparison of C, Z, and CZ interchangeable purlin machines, covering structural differences, production methods, operational efficiency, cost considerations, and real-world application scenarios.