This high-performance roll forming machine is engineered for the precision manufacturing of storage rack components, such as upright frames and beams. It features a robust construction, automated PLC control, and quick-change tooling to ensure high output, consistent quality, and minimal downtime. It is the ideal solution for storage system manufacturers seeking to boost production efficiency and product reliability.

Main Components

| Hydraulic Decoiler with Pre-leveling device | Holds and feeds steel coils smoothly into the line. |

| Roller feeder by a Servo motor | |

| 110T Press | |

| Roll Forming Machine | Precision-engineered rollers shape steel into into different profiles with accuracy. |

| Hydraulic Flying Cutting System with pin-insert design | Provides fast, clean, and burr-free cuts to required lengths. |

| Output Table with pneumatic un-loading function | User-friendly interface for automatic operation and easy adjustments. |

| Control System (PLC + Touch Screen) | Collects finished products for efficient handling and packaging. |

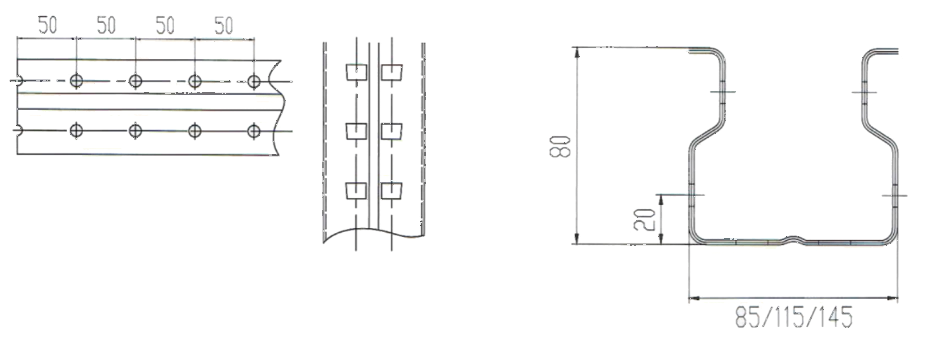

Drawing

Key Features

- High-Strength Forming: Capable of processing high-tensile steel to produce durable racks with excellent load-bearing capacity.

- Precision Engineering: Advanced servo technology and a multi-stand forming mill guarantee precise dimensional accuracy and consistent profile geometry.

- Rapid Changeover: Patented quick-release mechanism for rolls and guides slashes tooling changeover time, enabling flexible, small-batch production.

- Fully-Automated Operation: Integrated PLC with touchscreen HMI allows for easy setup, real-time monitoring, and fault diagnosis. Options include automatic punching, notching, and cutting.

- Durability & Stability: Reinforced frame and precision-machined gearbox ensure smooth, vibration-free operation and a long service life, even under heavy-duty cycles.

Technical Specifications

| Material | Type | GI,cold-rolled steel |

| Thickness(mm) | 1.5-4.0 | |

| Yield Strength(Mpa) | 230-350 | |

| Forming Speed(m/min) | 15-45 | |

| Roller Station | Depends | |

| Roller Material | Cr12 steel with hard chrome treatment | |

| Roller Driven Type | Chain transmission/Gearbox | |

| Shaft Material | 45# steel with heat treatment | |

| Shaft Diameter | Ø80-90 mm | |

| Control System | PLC+Touch screen and button | |

| Main Machine Power(KW) | 15-30(or customized) | |

| Hydraulic station Power(KW) | 7.5 | |

| Machine Weight(Kg) | 10500 | |

| Machine size(m) | 10.5×1.8×1.9 Depend on final design | |